boundary objects

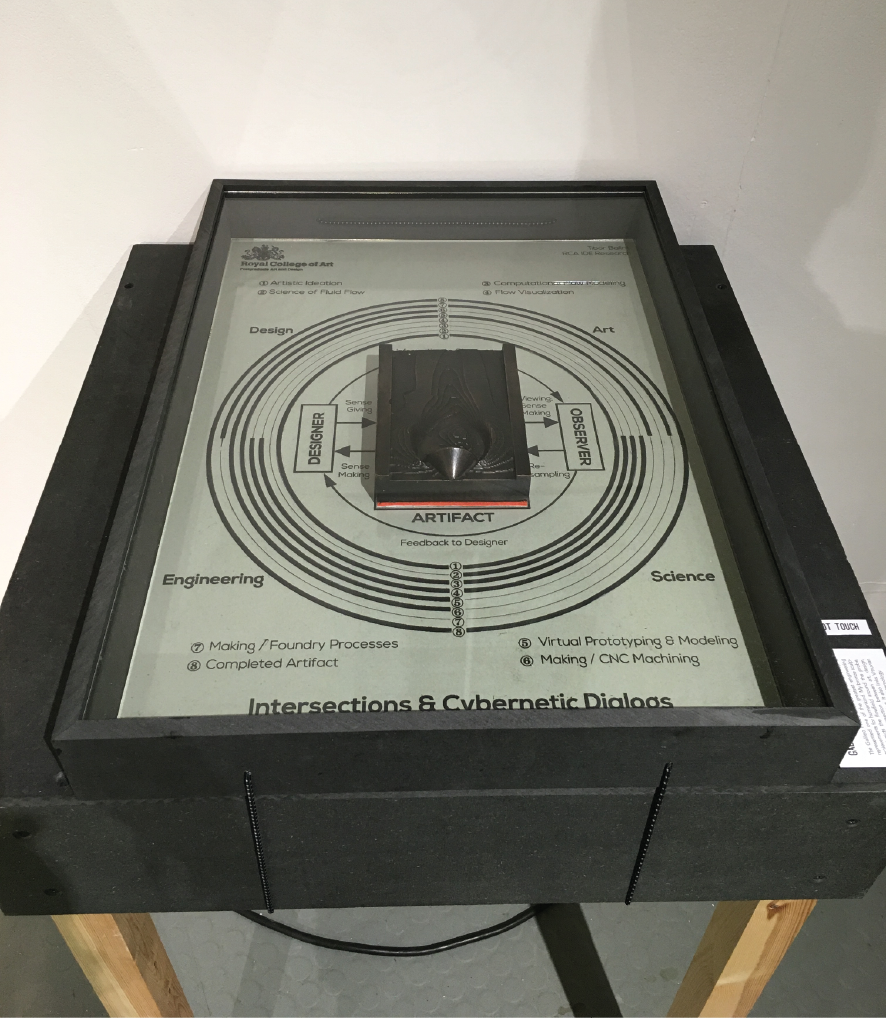

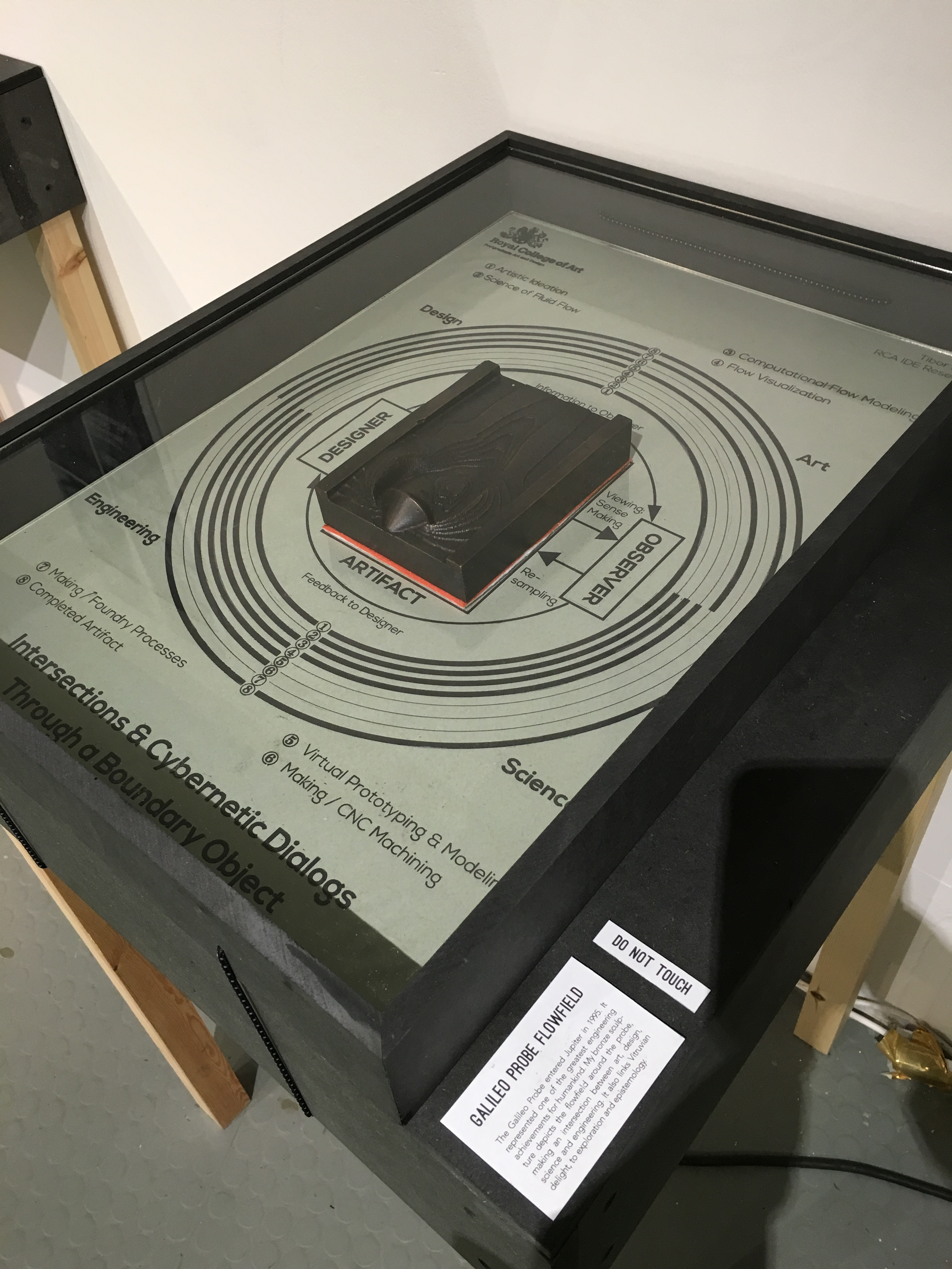

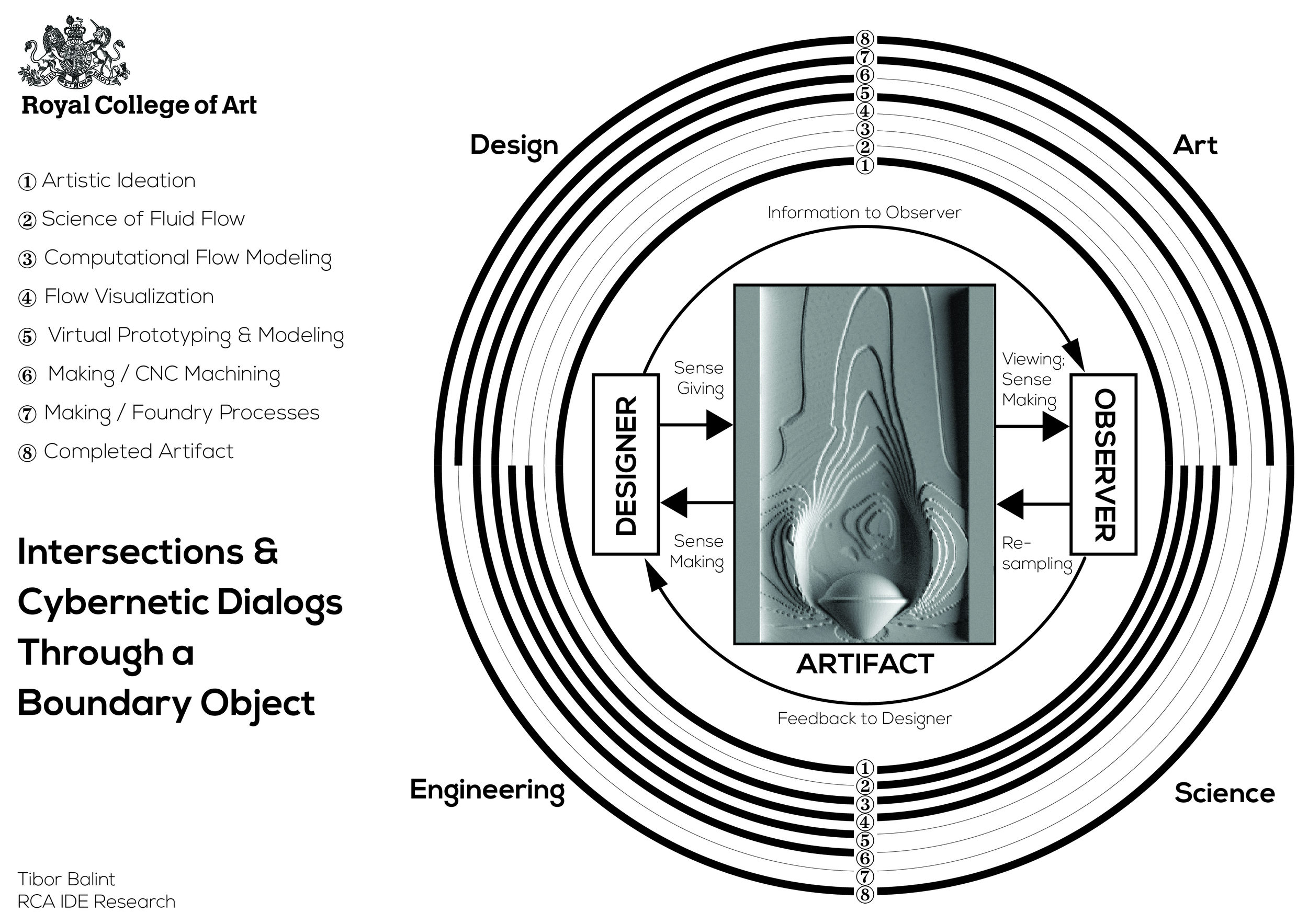

Boundary objects are typically created and used to communicate ideas across different disciplines and reach a constructivist middle ground while discussing ideas, concepts, and solutions. Disciplines in the examples below include design, art, science, and engineering. They can facilitate dialogs during the concept development process, but they can be also used as demonstration elements, when conveying messages to external audiences. Thus a boundary object can be a vague representation of an idea during the ideation phase. Creating the object represents the sense giving part of a dialog. In the sense making feedback loop each team member interprets it, which might provoke ideas beyond the envisioned initial concept from the person who created it. The vagueness of the boundary object, combined with the broadened variety of the environment—which consists of the team members—can introduce new variety to the discourse. Through dialogs the team members can converge on a novel meaning, that helps to refine the concept or it can lead to new preferred outcomes and solutions.

bronze boundary objects

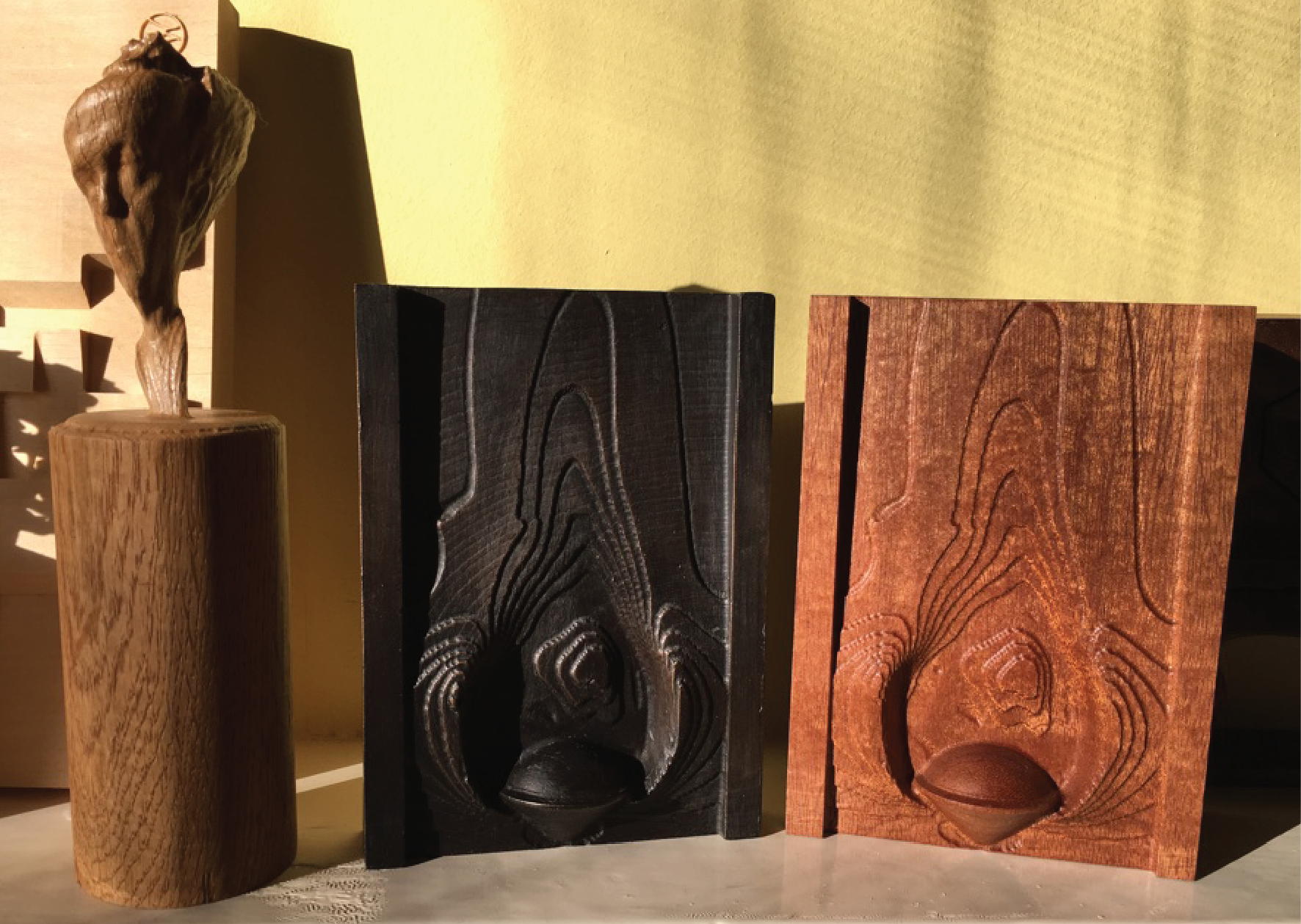

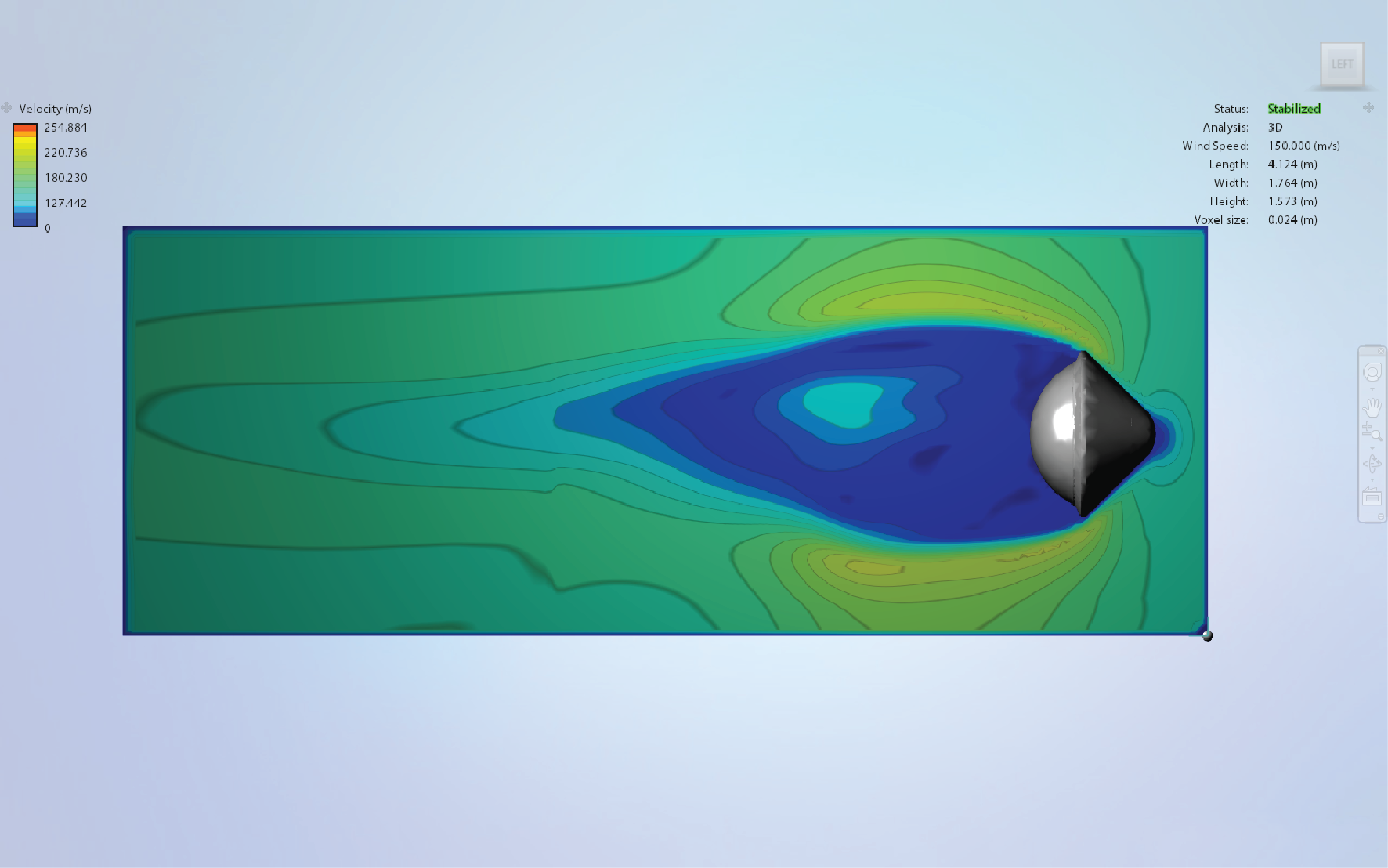

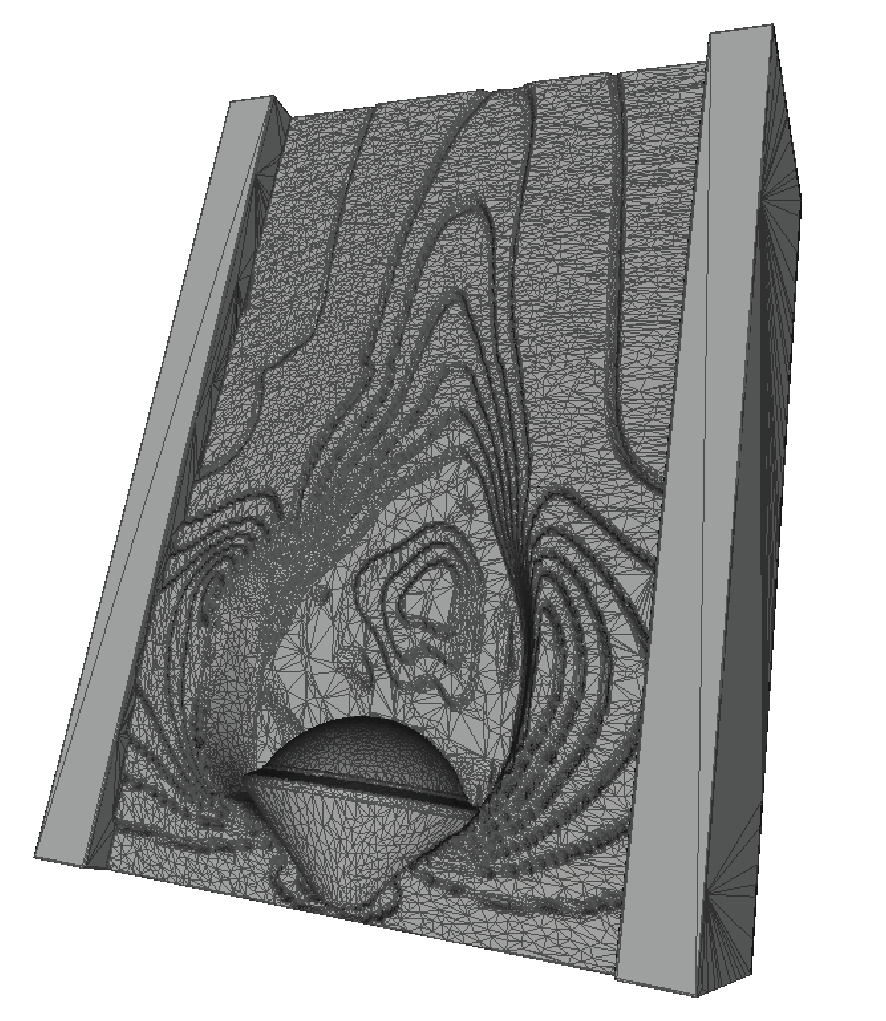

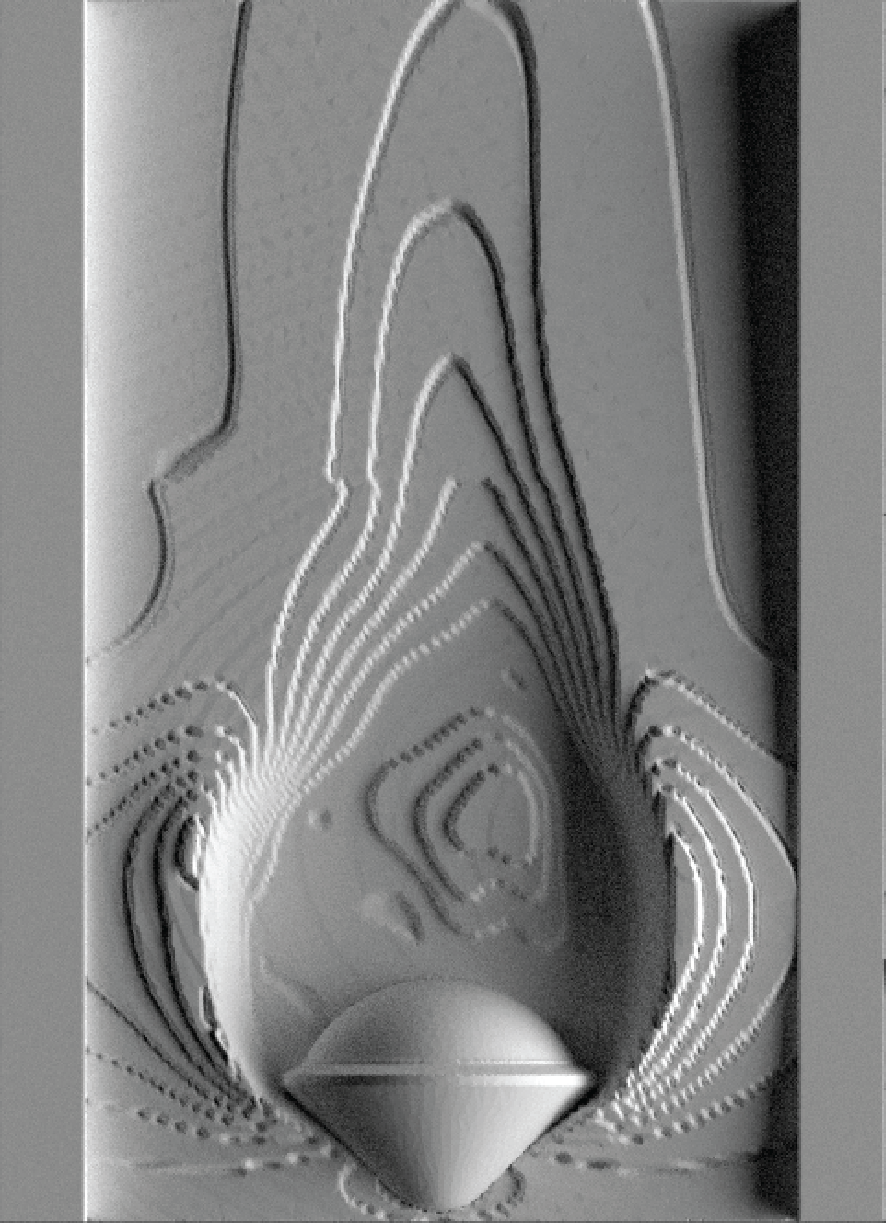

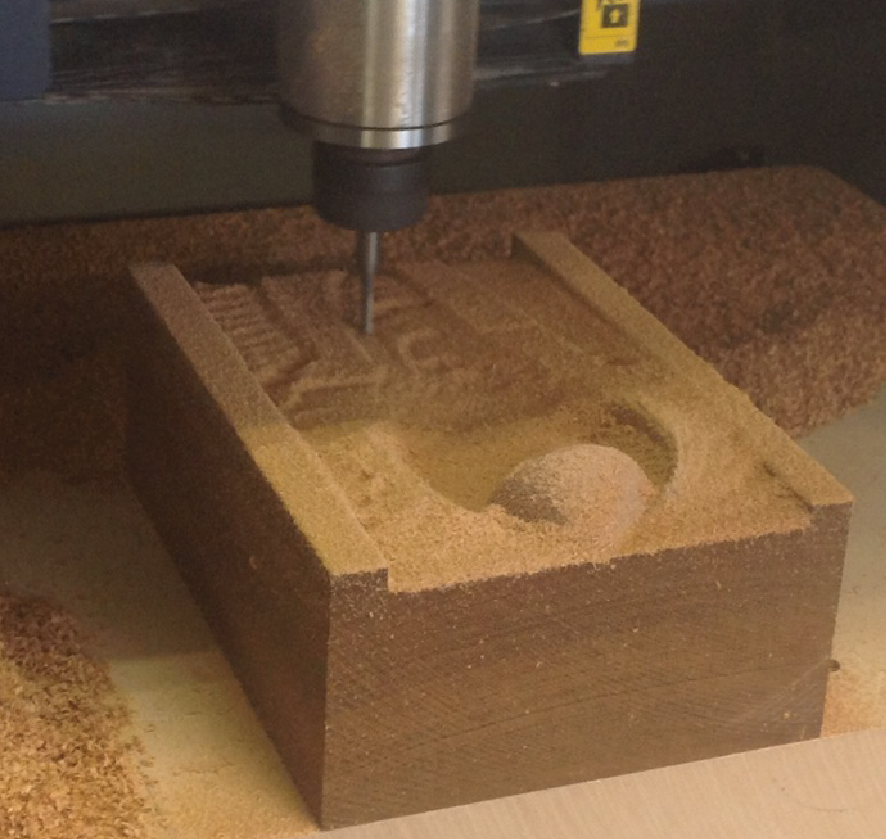

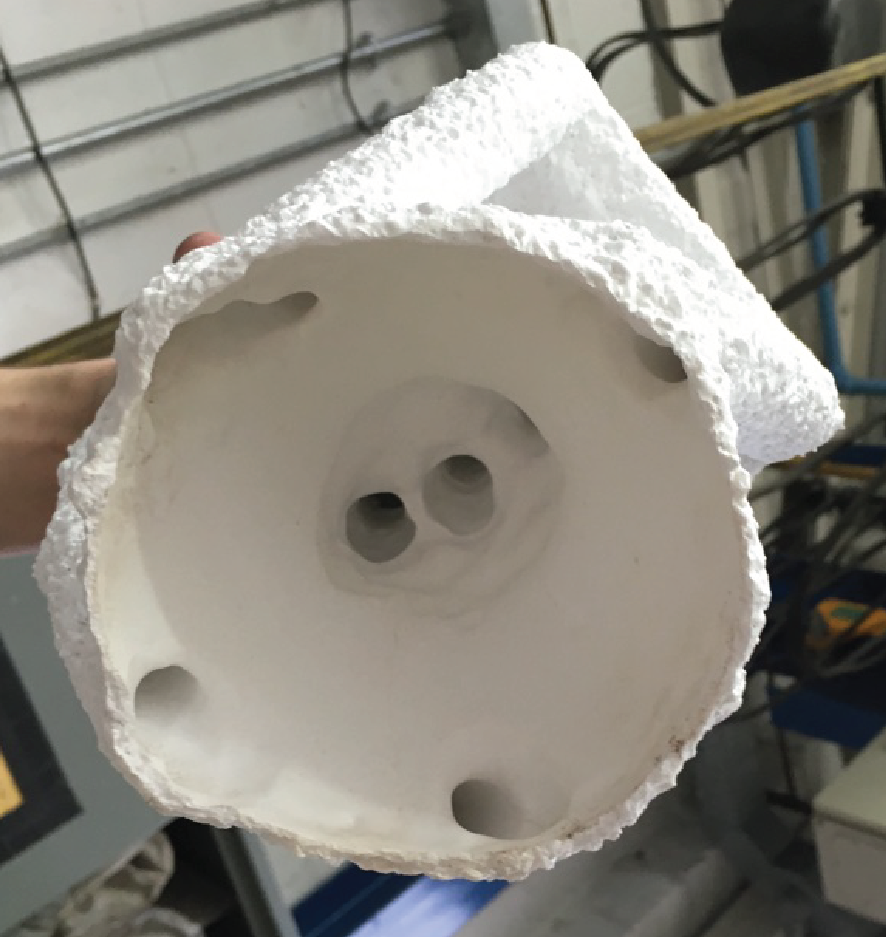

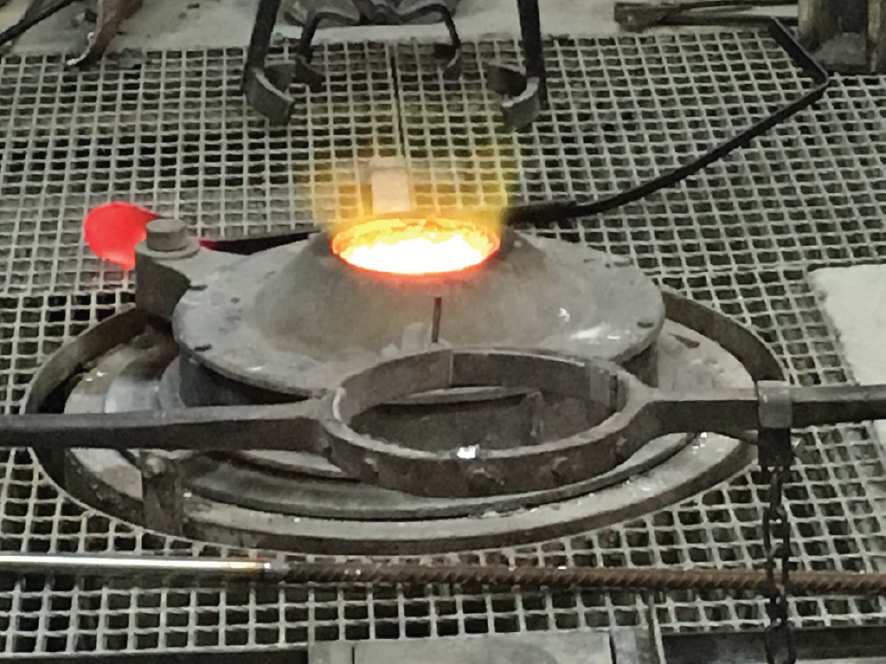

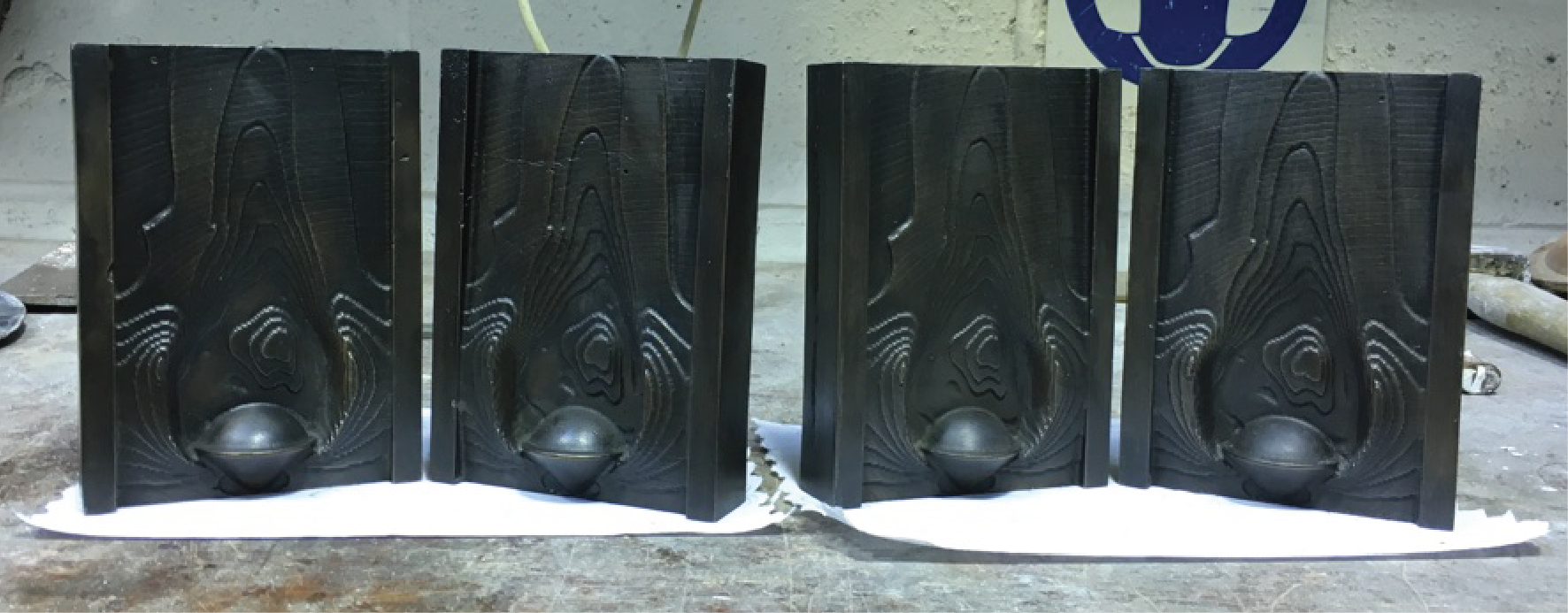

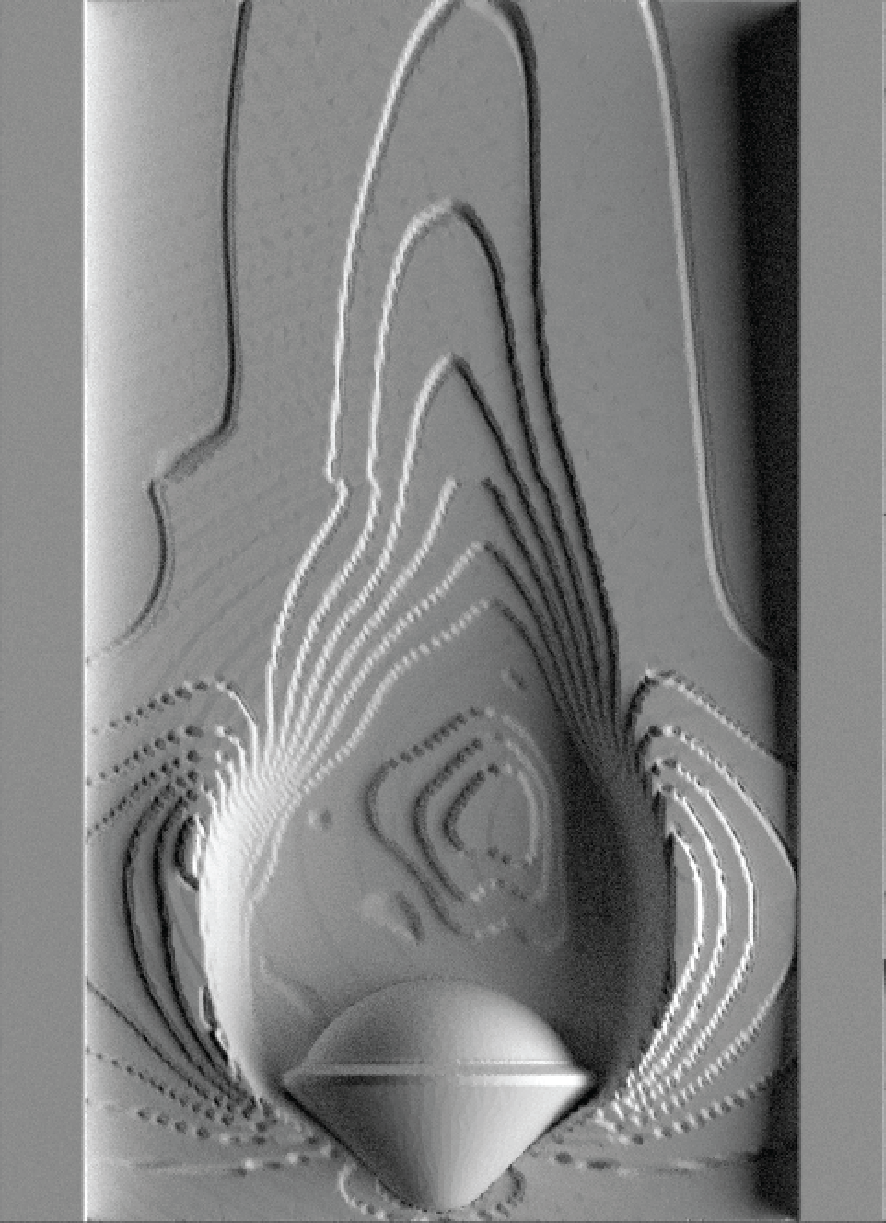

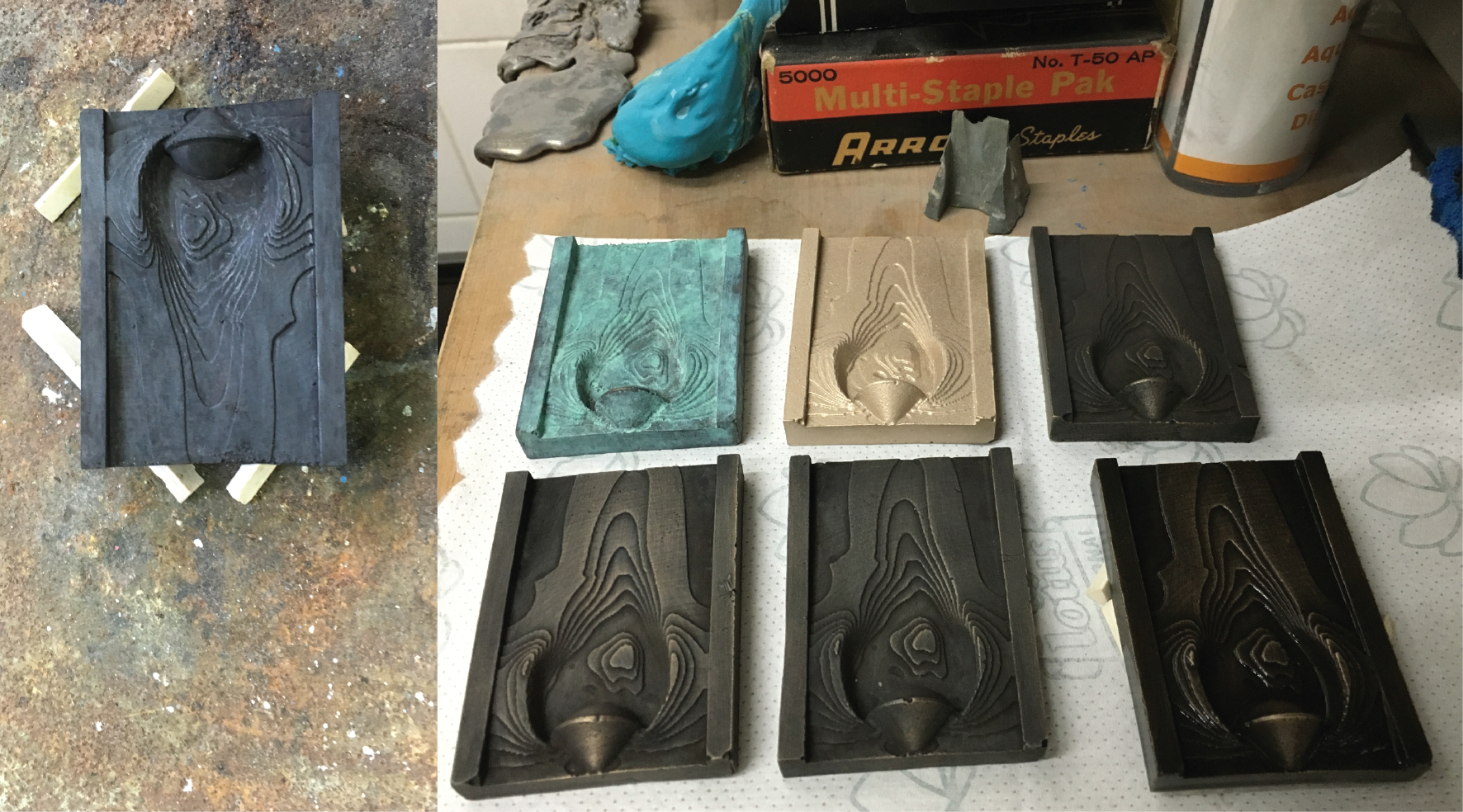

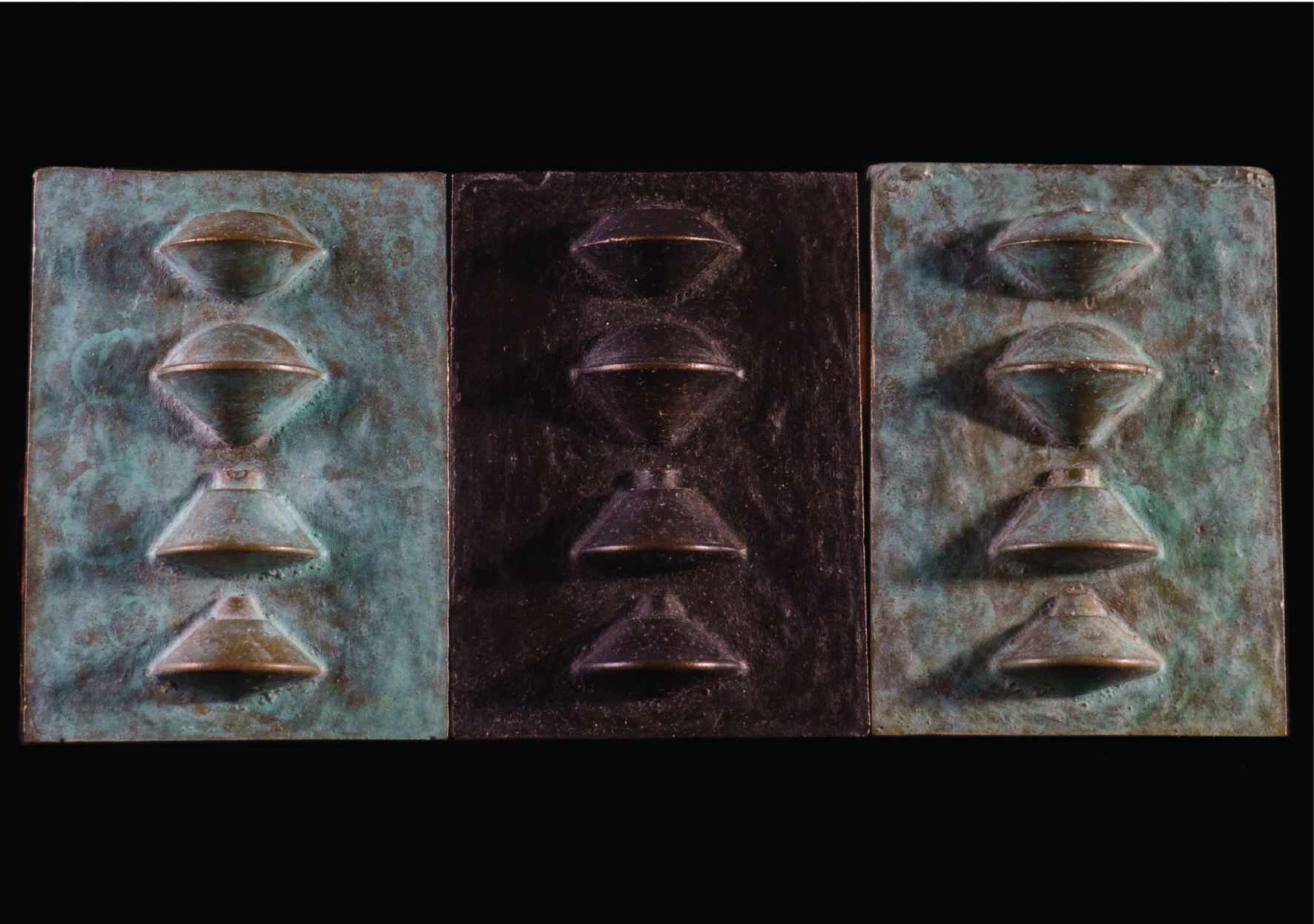

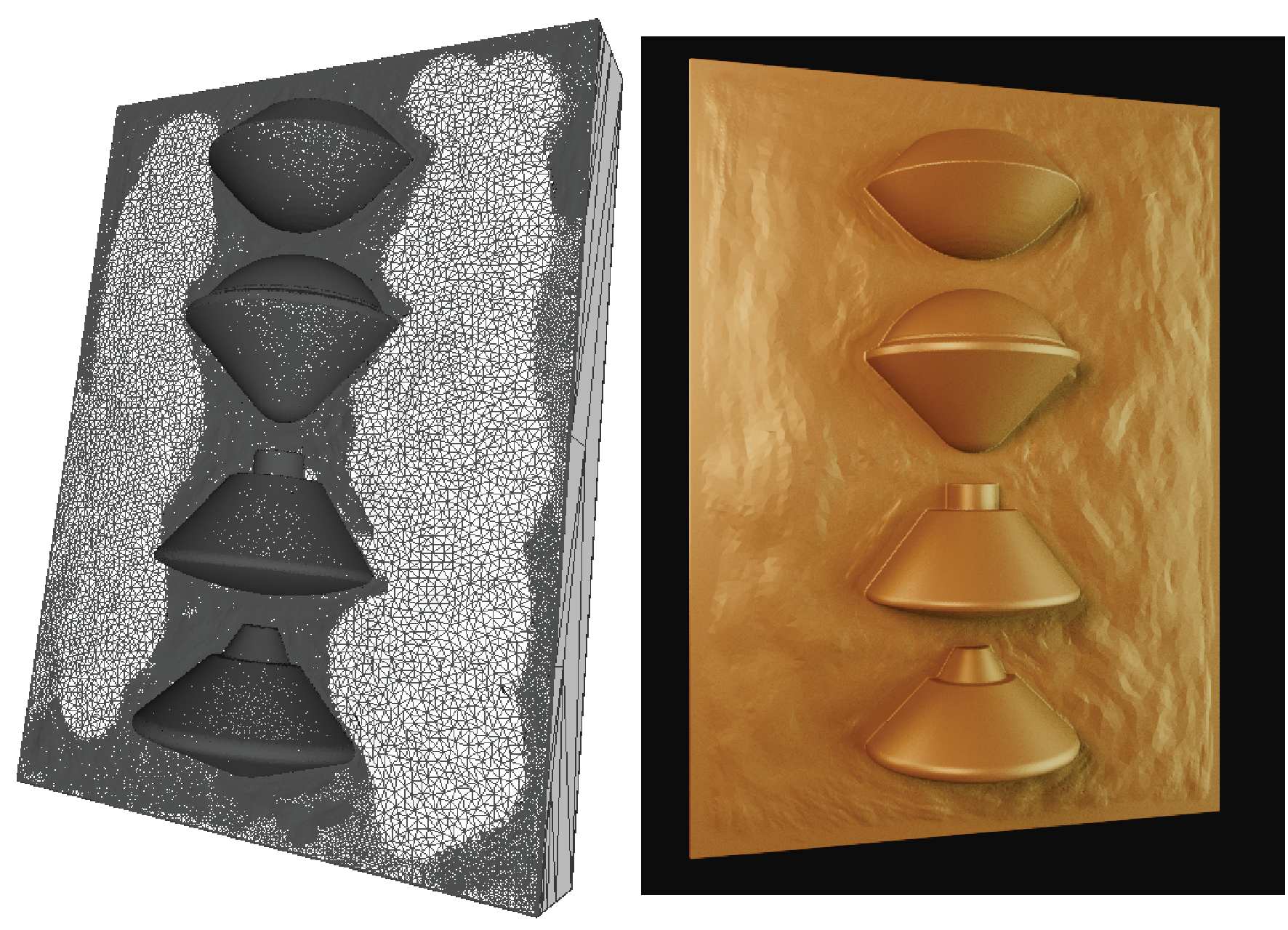

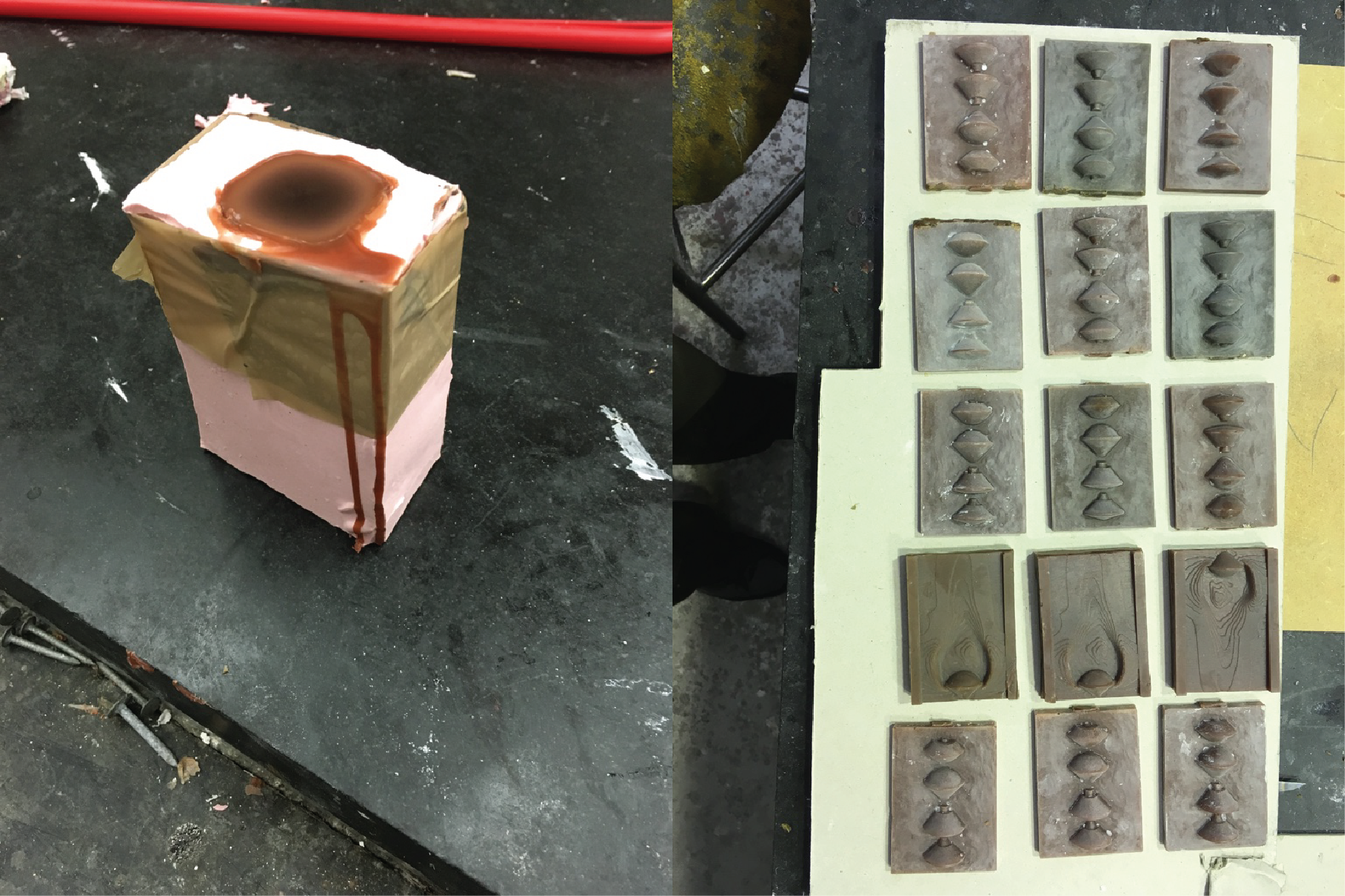

"Galileo Flow Field" boundary object. I have created them using flow simulation (science and engineering), CNC machining (engineering and design) with great help from RCA's Digital Aided Making (DAM) staff, and Foundry work (design and art) at RCA's Sculpture department, with great support from Foundry staff. These boundary objects and others facilitate dialogs between disciplines. These dialogs can lead to novel shared languages and open up new possibilities. The sculpture depicts a Galileo type aeroshell in a flow field. I have used the same design, made out of walnut, for the official IPPW13 poster. Each of the four artifacts are H16cm x W11.5cm x D4.5cm, with the weight ranges from 2.5kg to 3 kg.

This bronze sculpture, which was made using the ceramic shell process, won the REMET Student Casting Prize 2016 on May 27.

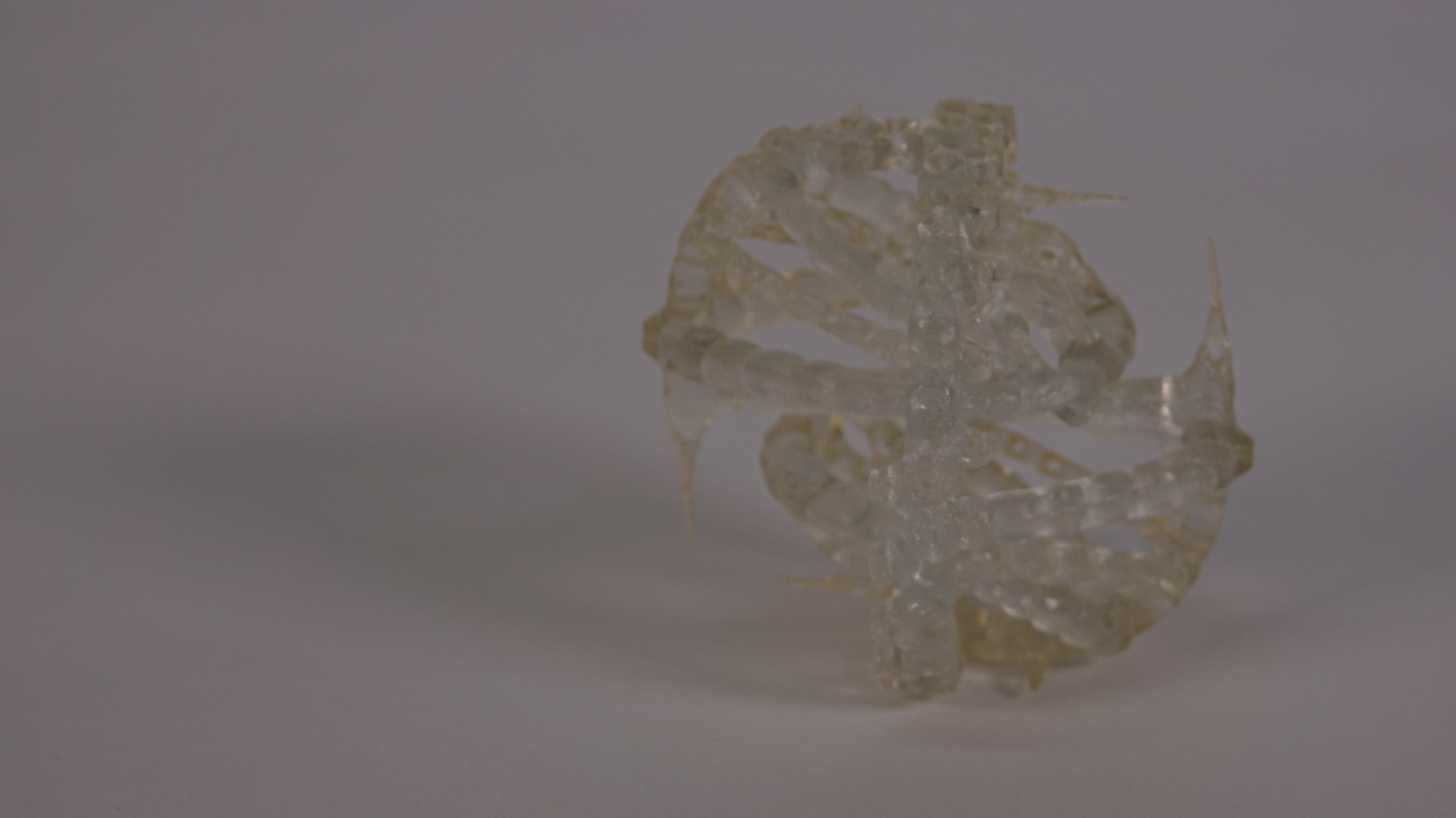

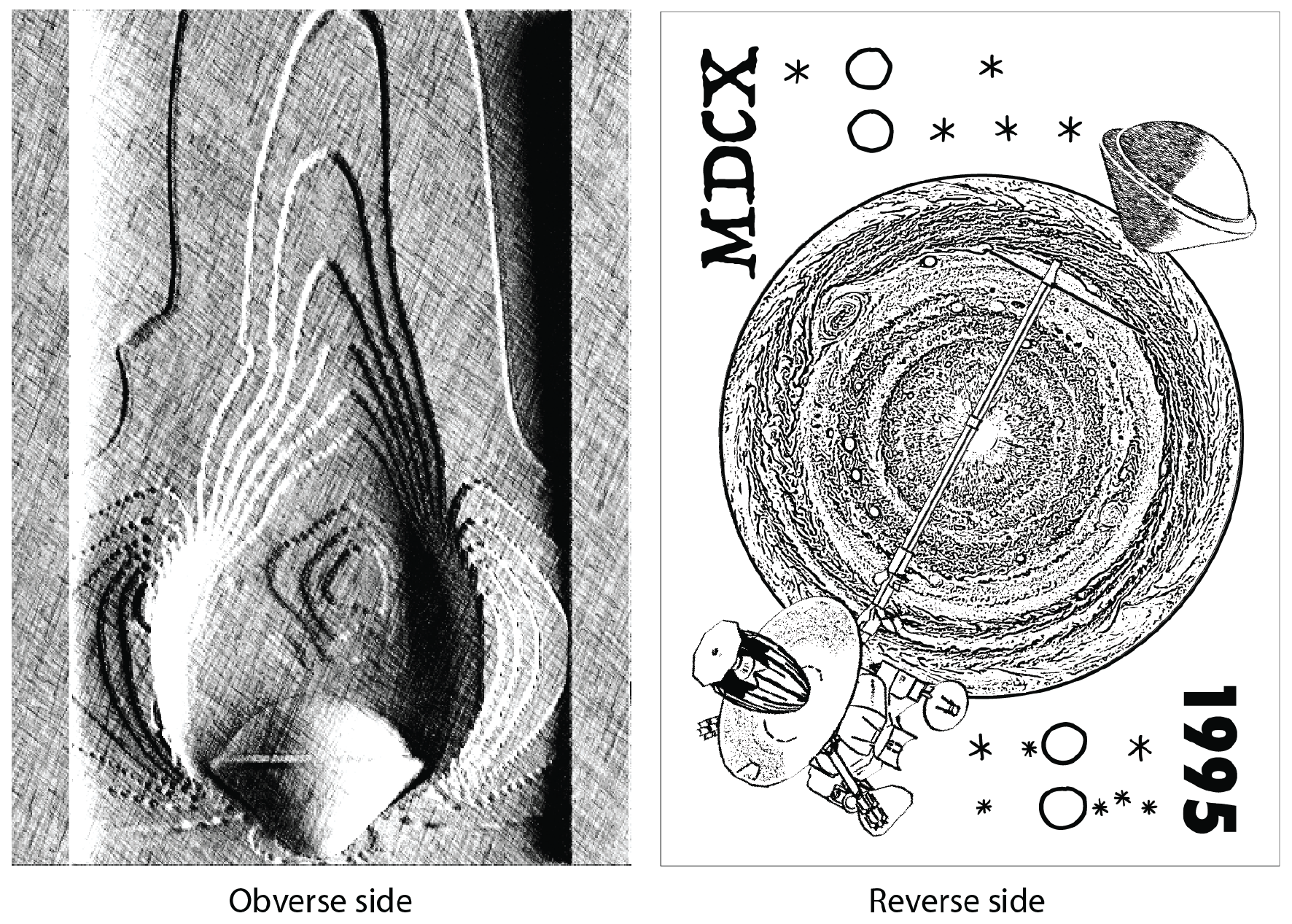

A derivative of the Galileo Flow Field model is the "Expanding Boundaries" medal that I have created in 2015, and submitted to the British Art Medal Society (BAMS) 2016 Student Competition. It was selected to for an exhibition at the Carmarthen School of Art at Coleg Sir Gar in September 2016. The obverse side is derived from the same model as the Galileo Flow Field design. The reverse side depicts two dates. In 1610 Galileo discovered four moons of Jupiter, while in 1995 the Galileo spacecraft delivered the Galileo probe for in-situ exploration of the planet. It also shows sketches from Galileo's notebook, with Jupiter and two, and three, then four moons. The center depicts Jupiter's polar view (at 10 o'clock the Great Red Spot is visible). The medal dimensions are H7cm x W5.1cm x D1.4cm, each weighting 0.2kg. Edition of 6, including five classic and one green patination.

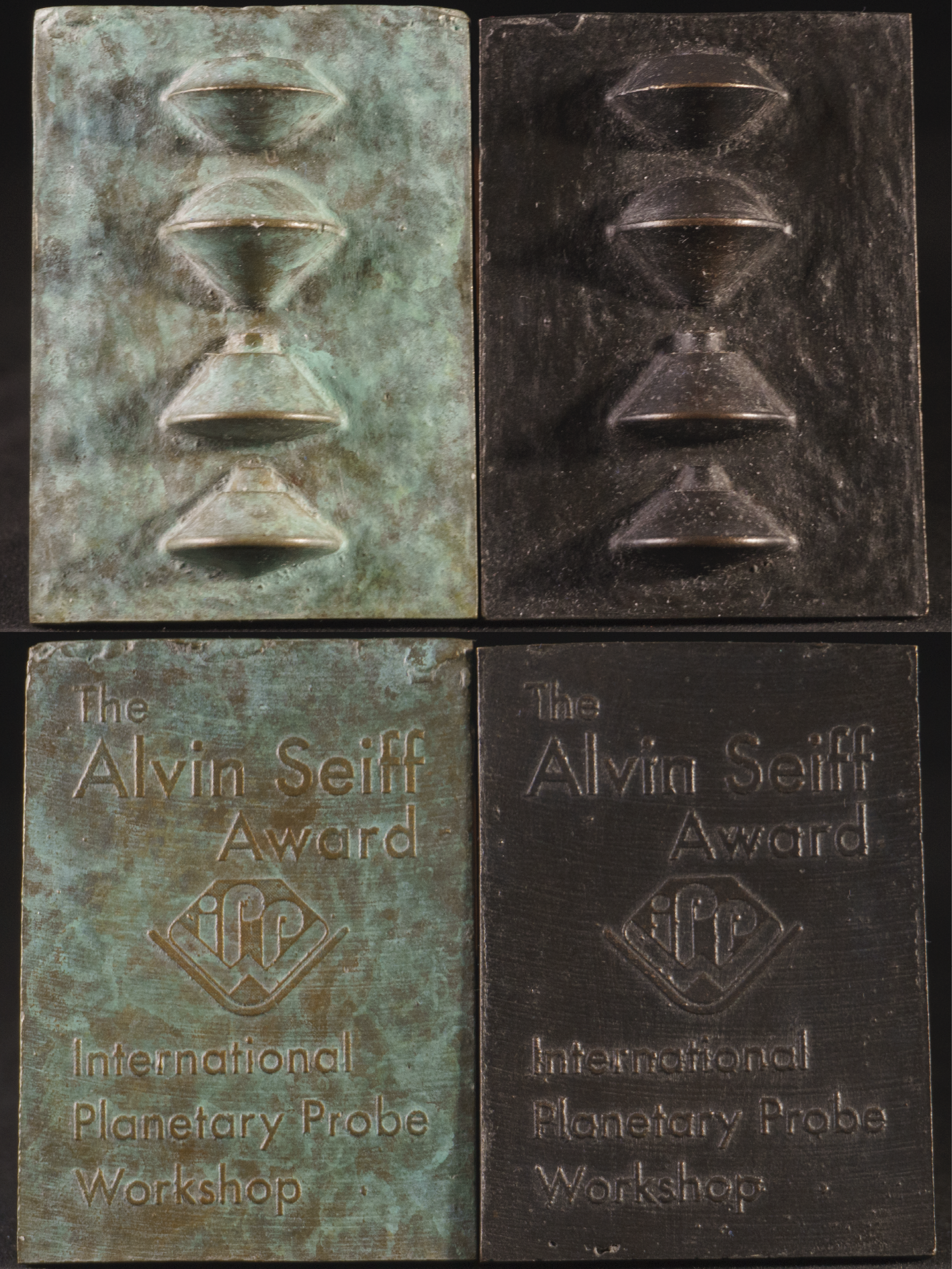

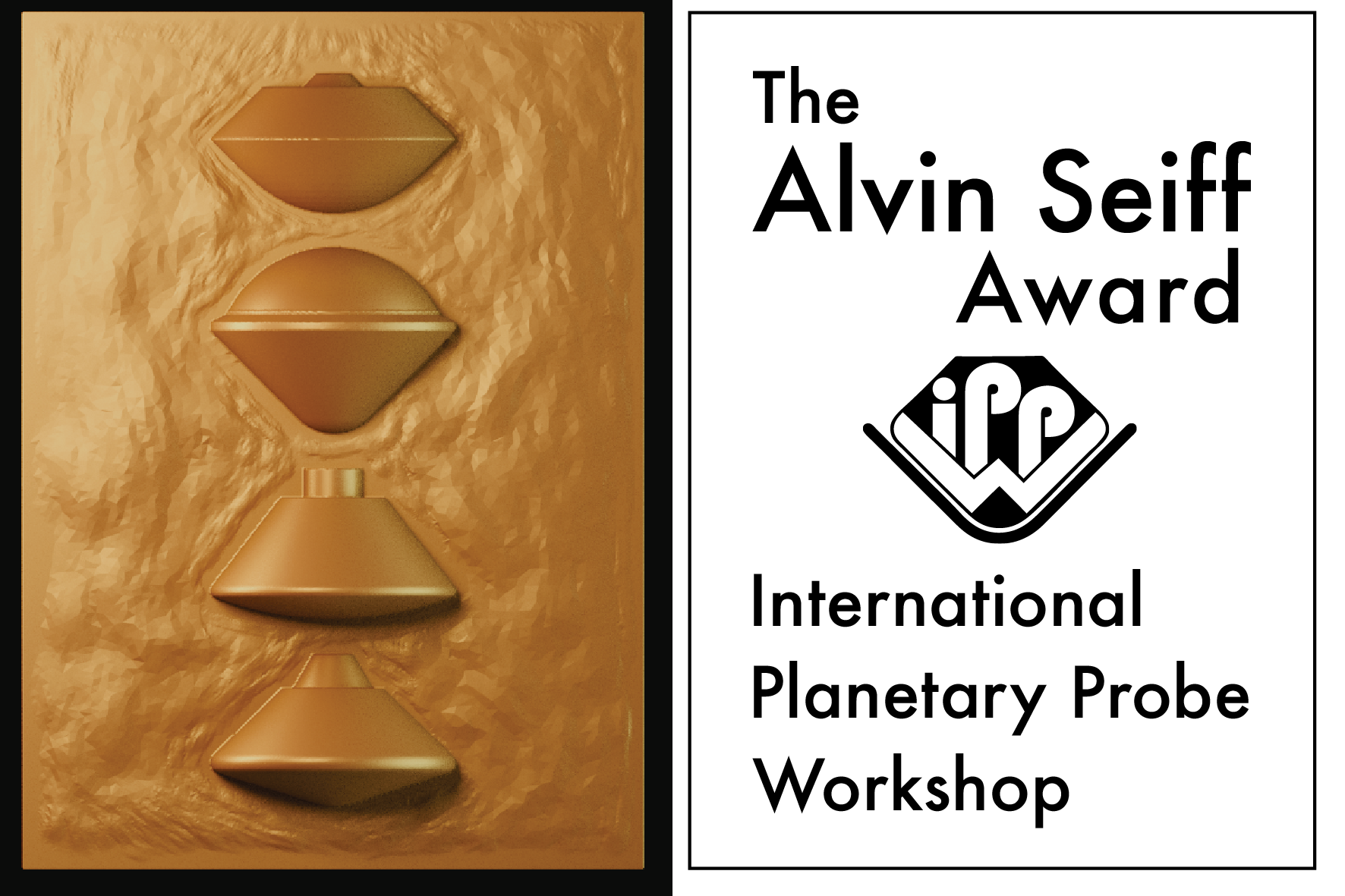

I have designed and created the "Alvin Seiff Memorial Award" medals in 2015/16 for our International Planetary Probe Workshop. We hand out achievement awards every year to a highly deserving expert. From this year on we will hand out the medal in addition to the certificate. The obverse side shows 4 aeroshells, in including Hayabusa, Galileo, ARD, and Phoenix. The reverse side names the awards, the workshop and shows the IPPW logo in the center. The medal dimensions are H7cm x W5.1cm x D1.4cm, each weighting 0.2kg. So far three were made.

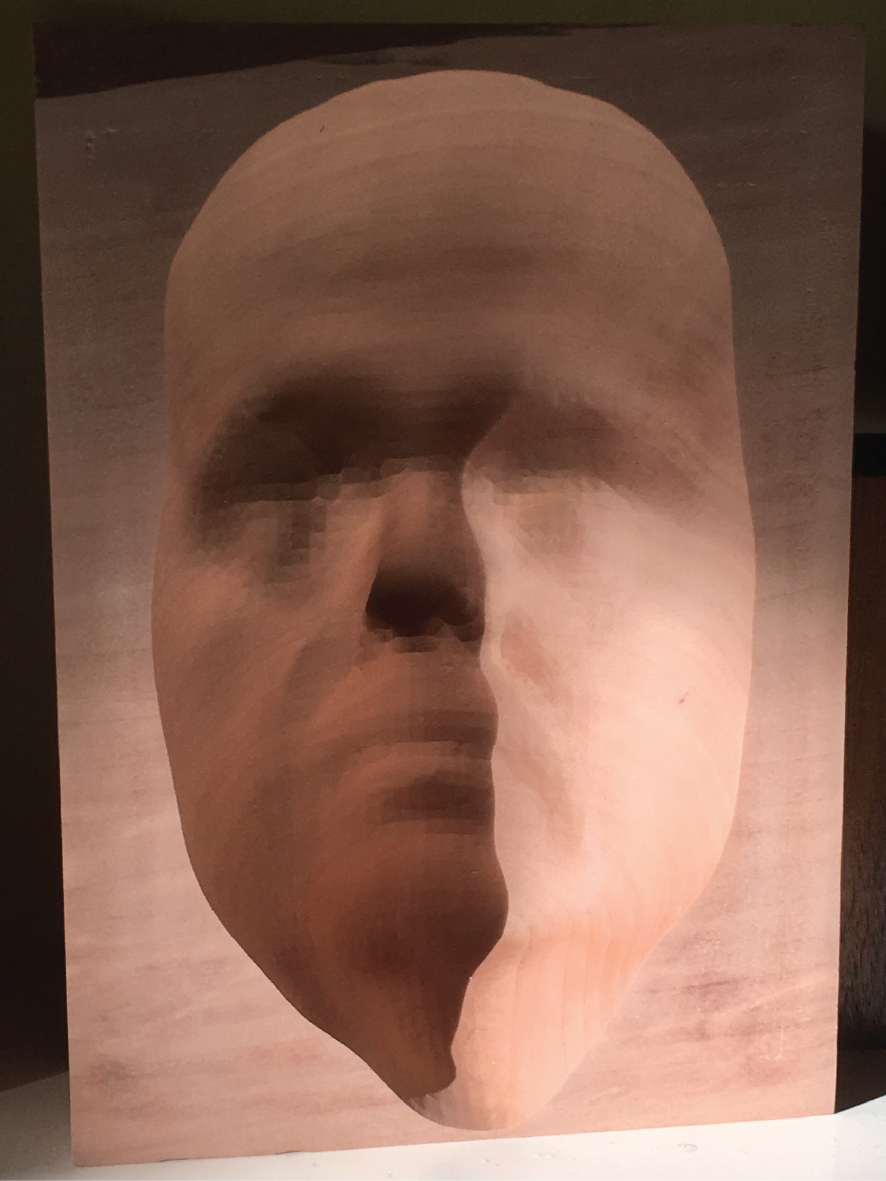

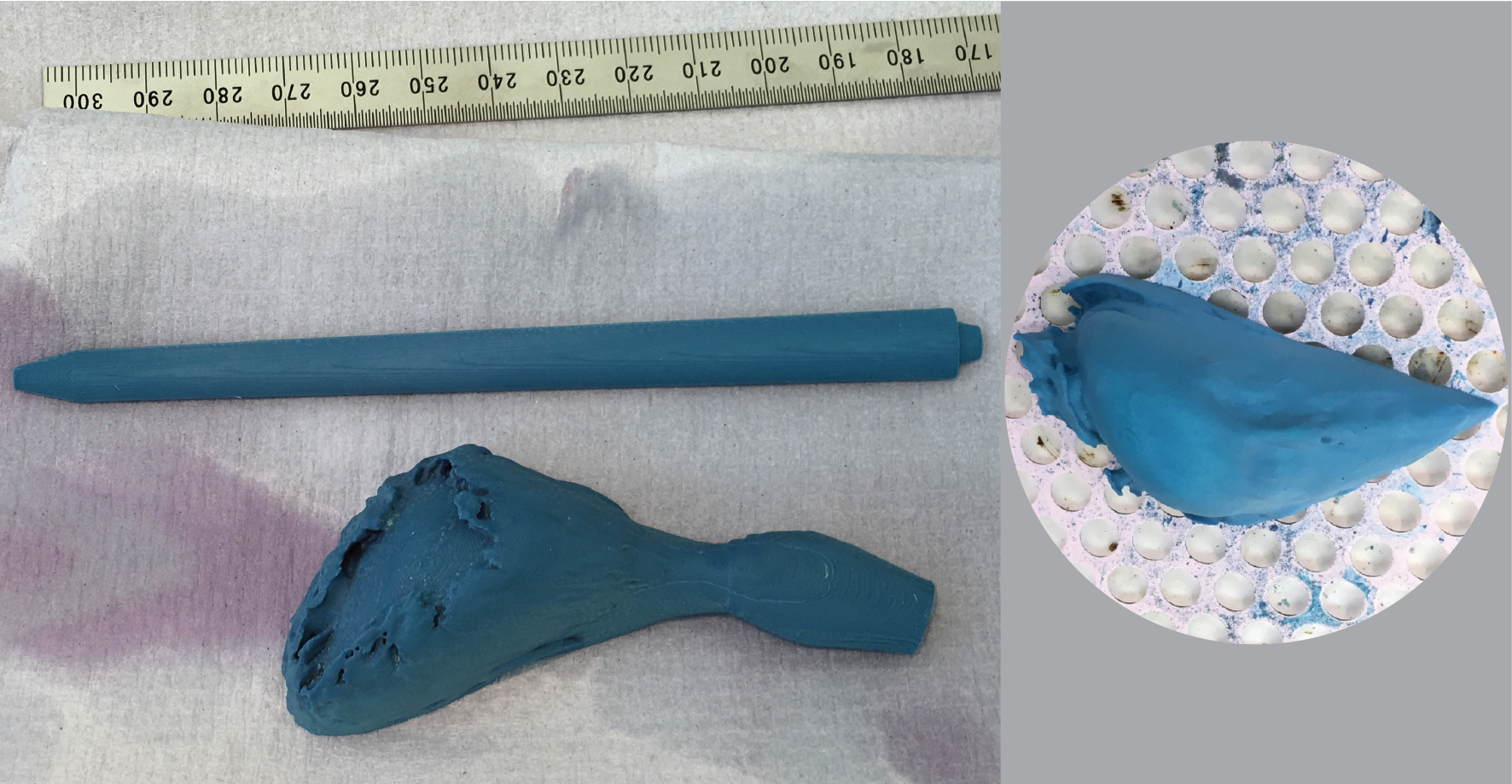

The "letter opener" started with my 3D scanned head, that I have modified in Blender3d using displacement modifiers. We have created an oak version on a 4-axis CNC machine at RCA's DAM. Then at the RCA's Jewelry department we 3D printed the letter opener model out of wax. I have used this wax master model at the Sculpture department for the silicone mold and subsequent making. They were created in 2015/16. Each final patinated bronze artifact is about 22cm long and weights 0.25kg. Edition of 8, with four classic and four green patination.

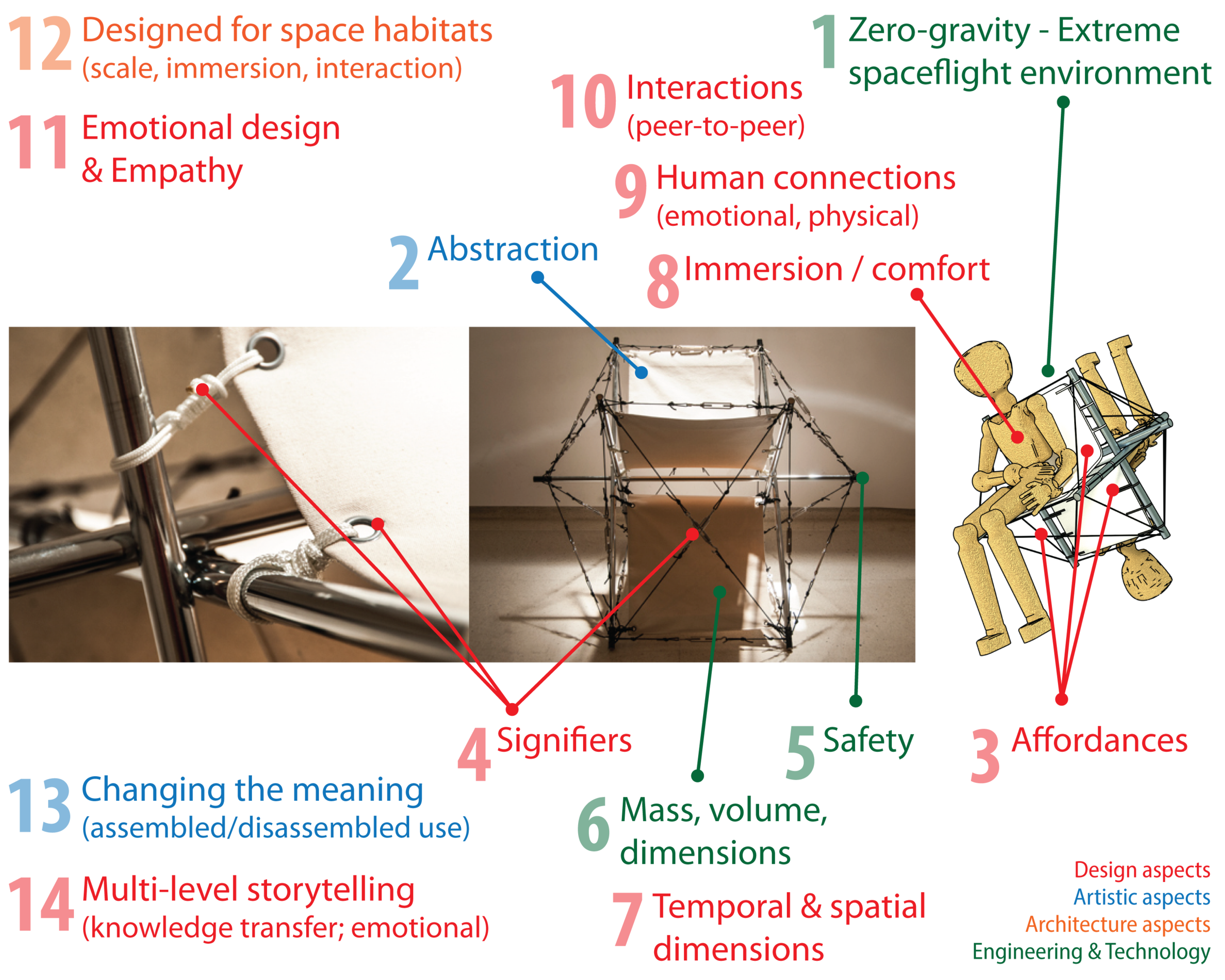

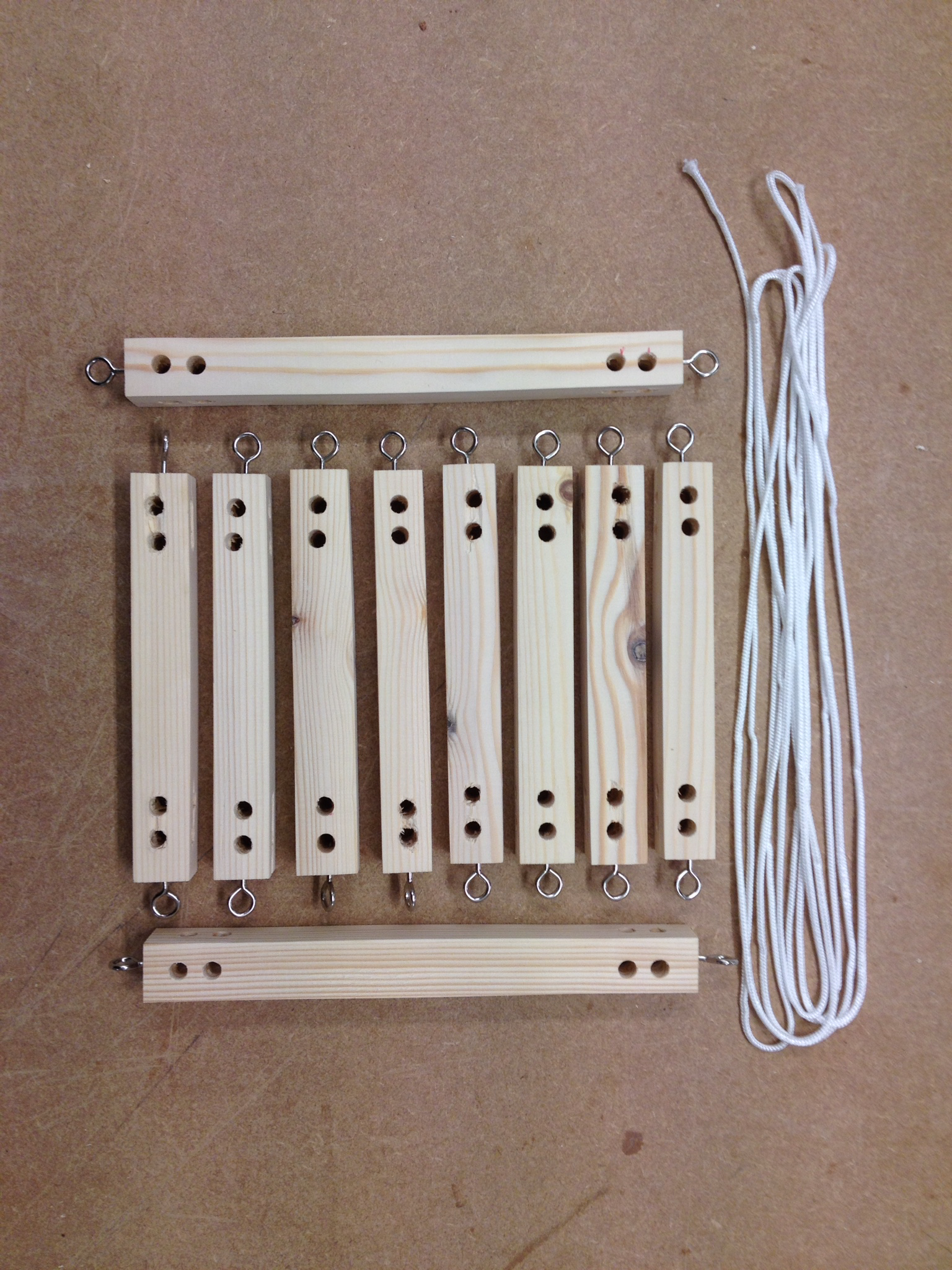

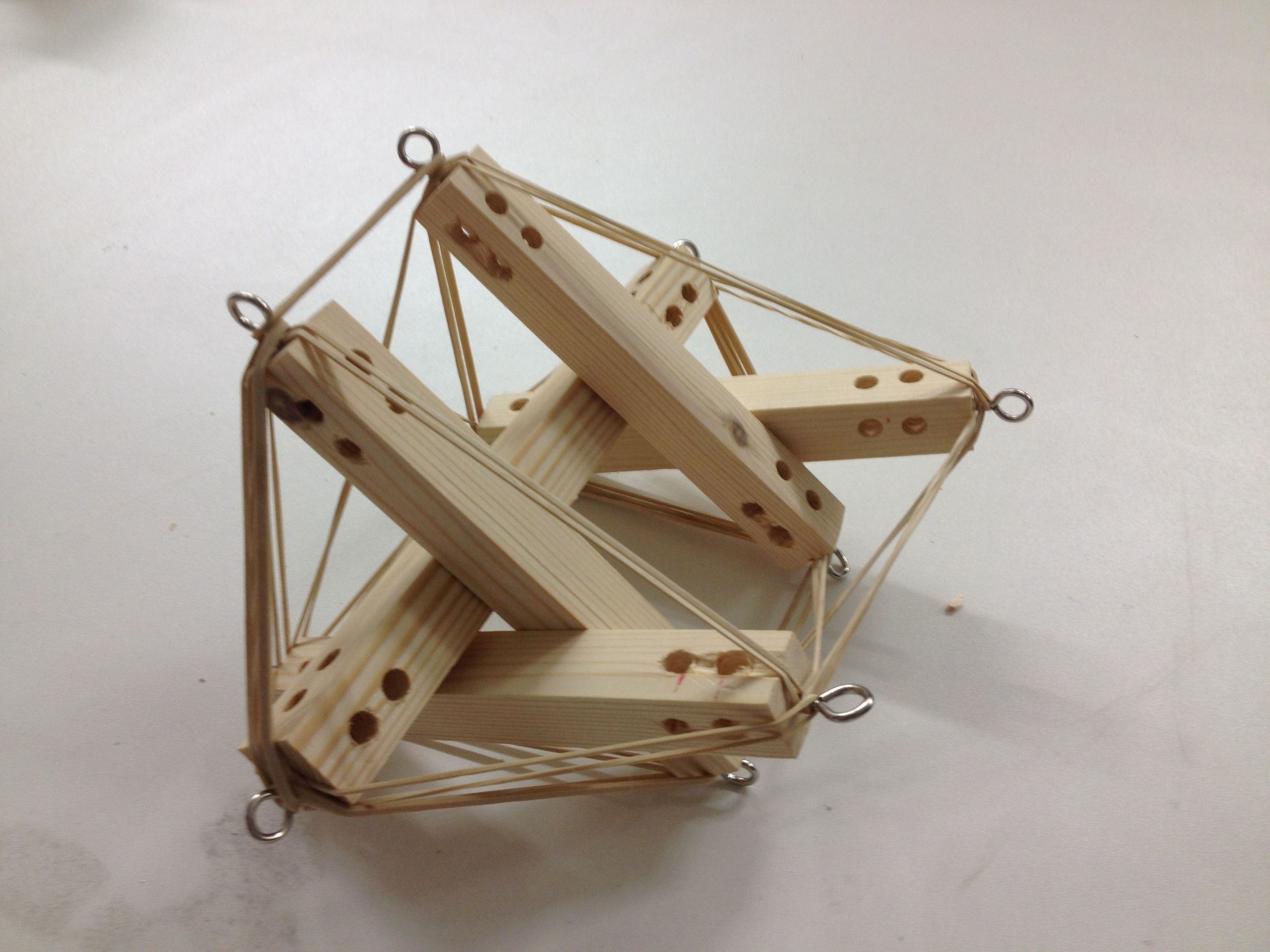

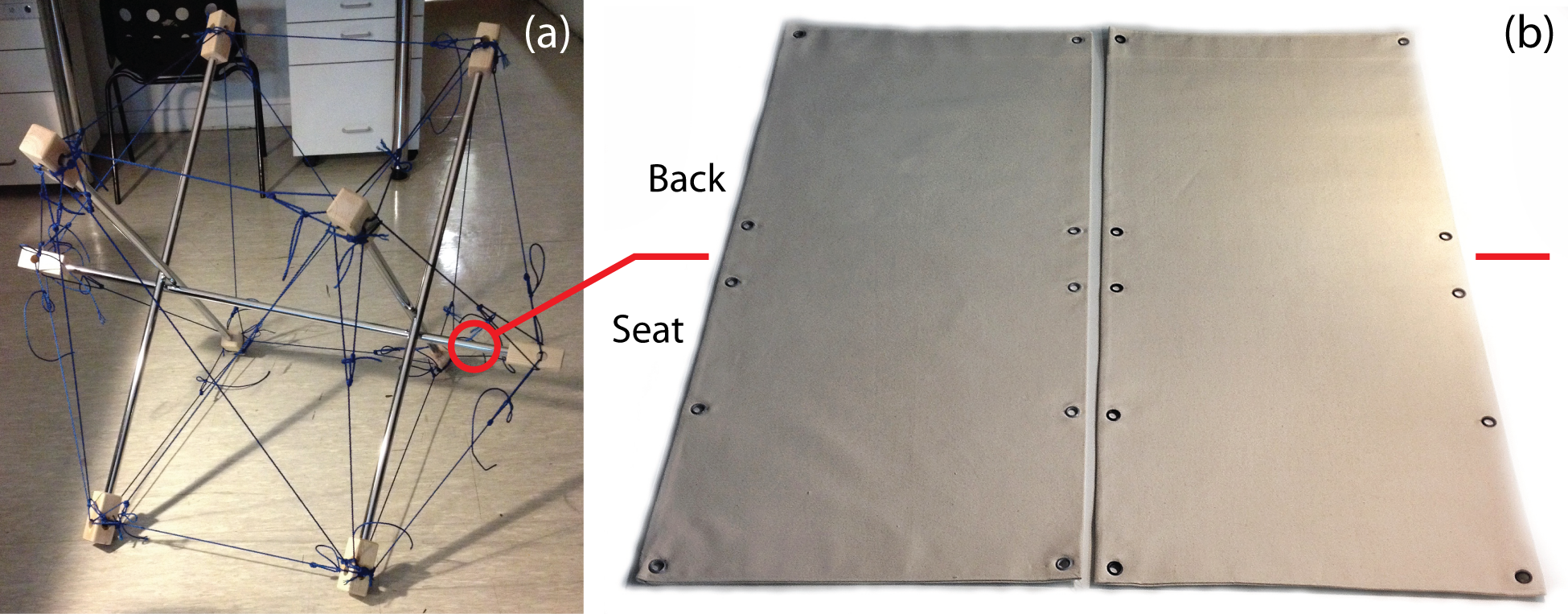

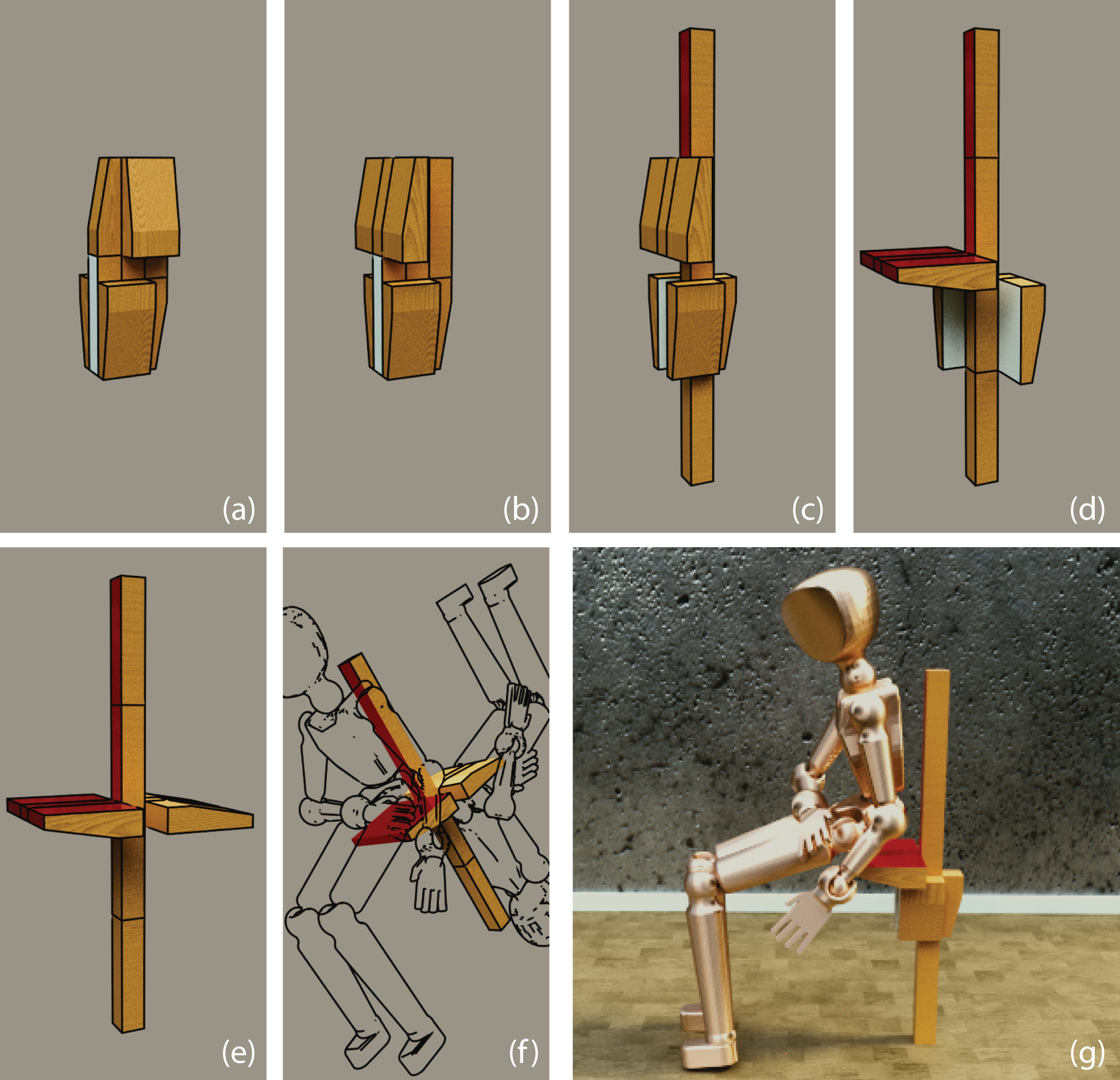

cybernetic astronaut chair

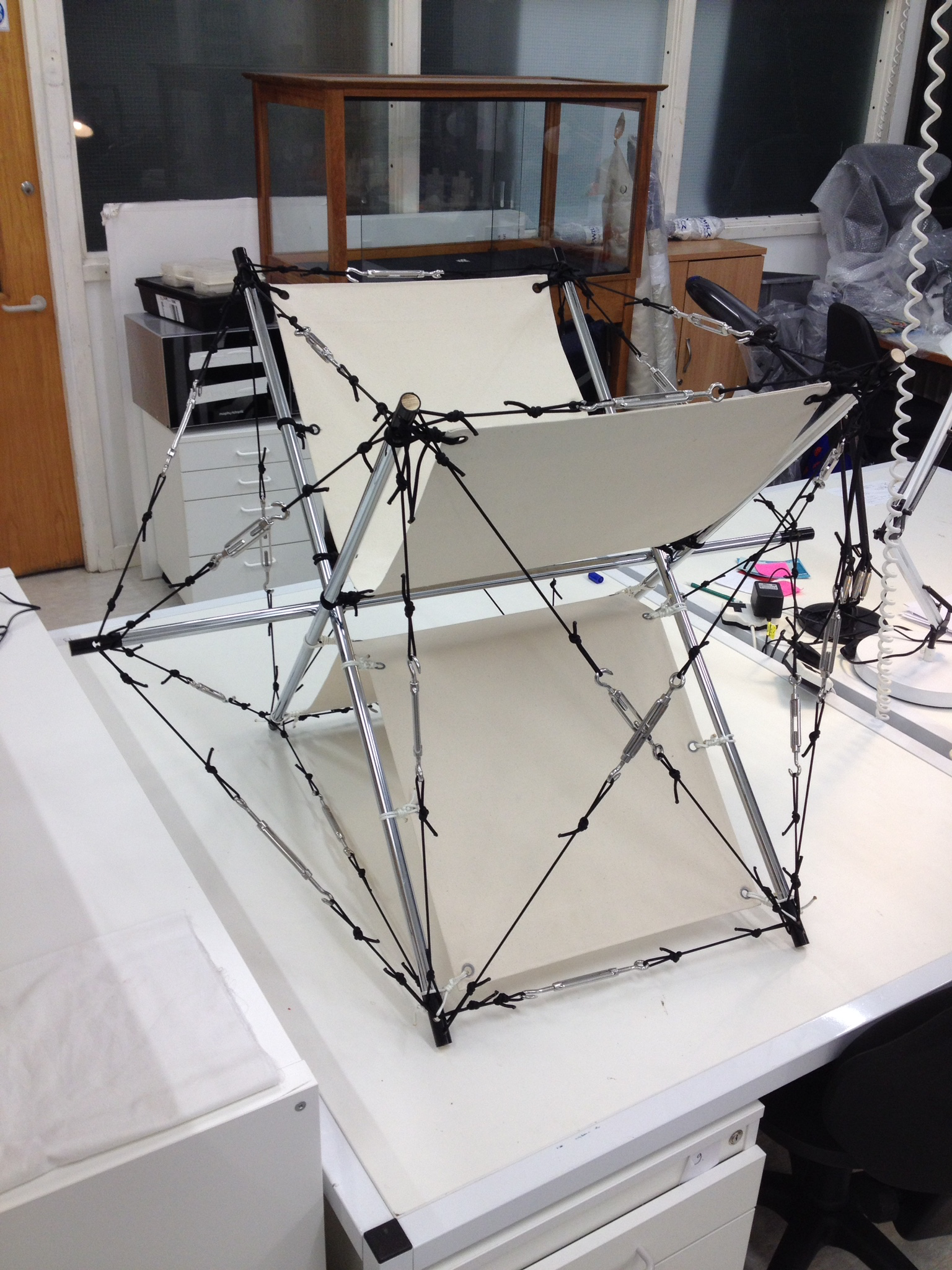

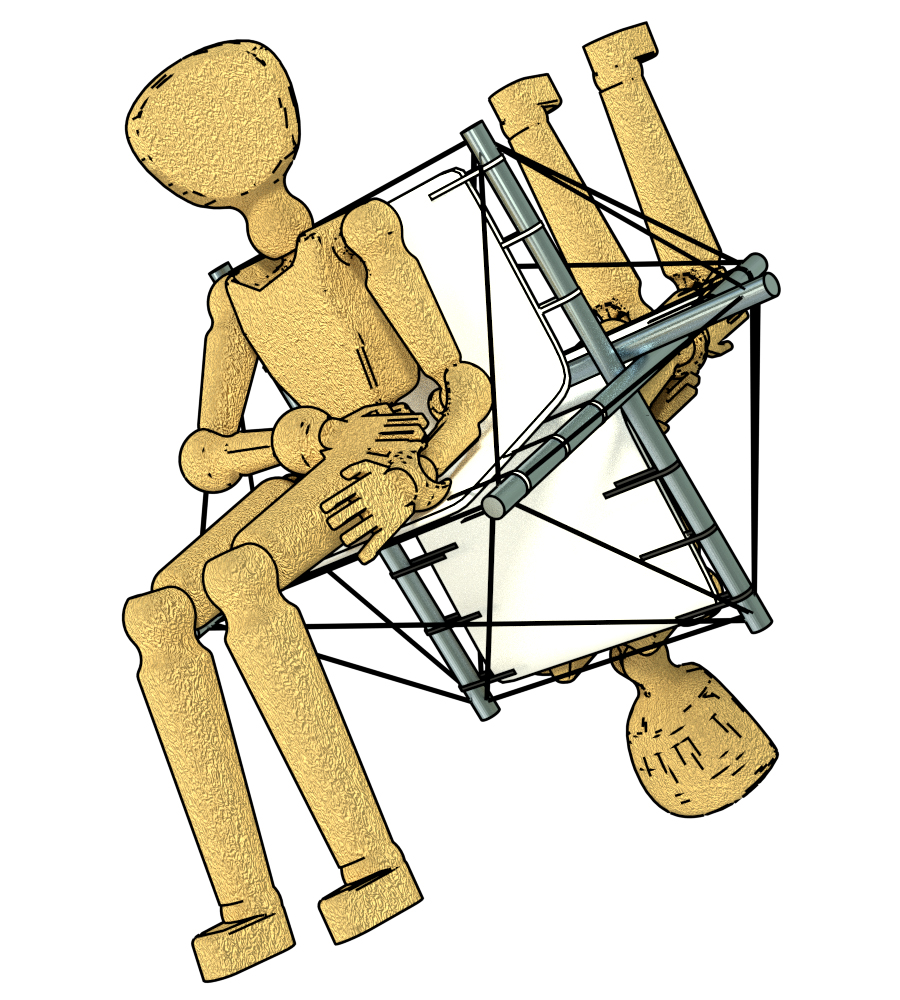

I have created this "cybernetic astronaut chair" in 2014, to highlight some of the considerations when designing for space missions. Cybernetic, because it provides a constructivist circular dialog between the designer and the observers (or notional users) through this object. It would accommodate two astronauts in a zero gravity environment, sitting back to back. Another reflection on circularity. Do we need a chair in space? No. Yet it can provide familiar comfort and a home away from home. Also, it wasn't meant to be a functional chair. Instead, I used it as a boundary object to facilitate dialogs over the topic. The chair is based on tensegrity structures (tension + integrity; with no joints).

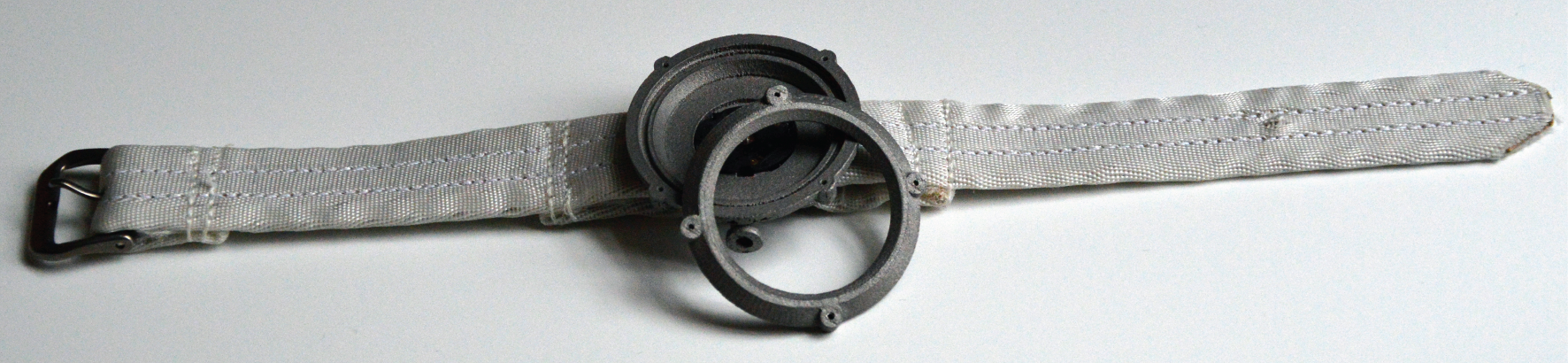

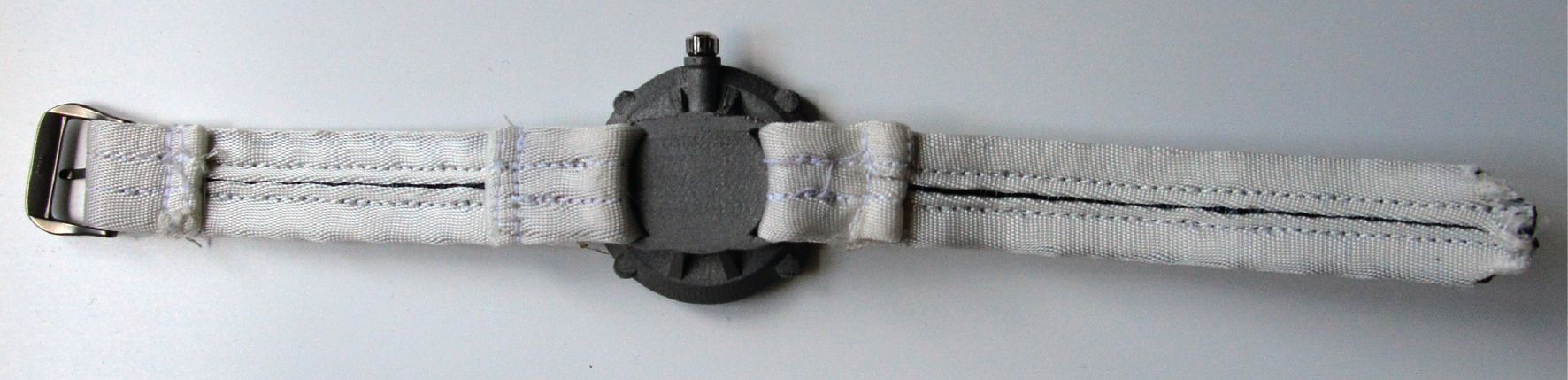

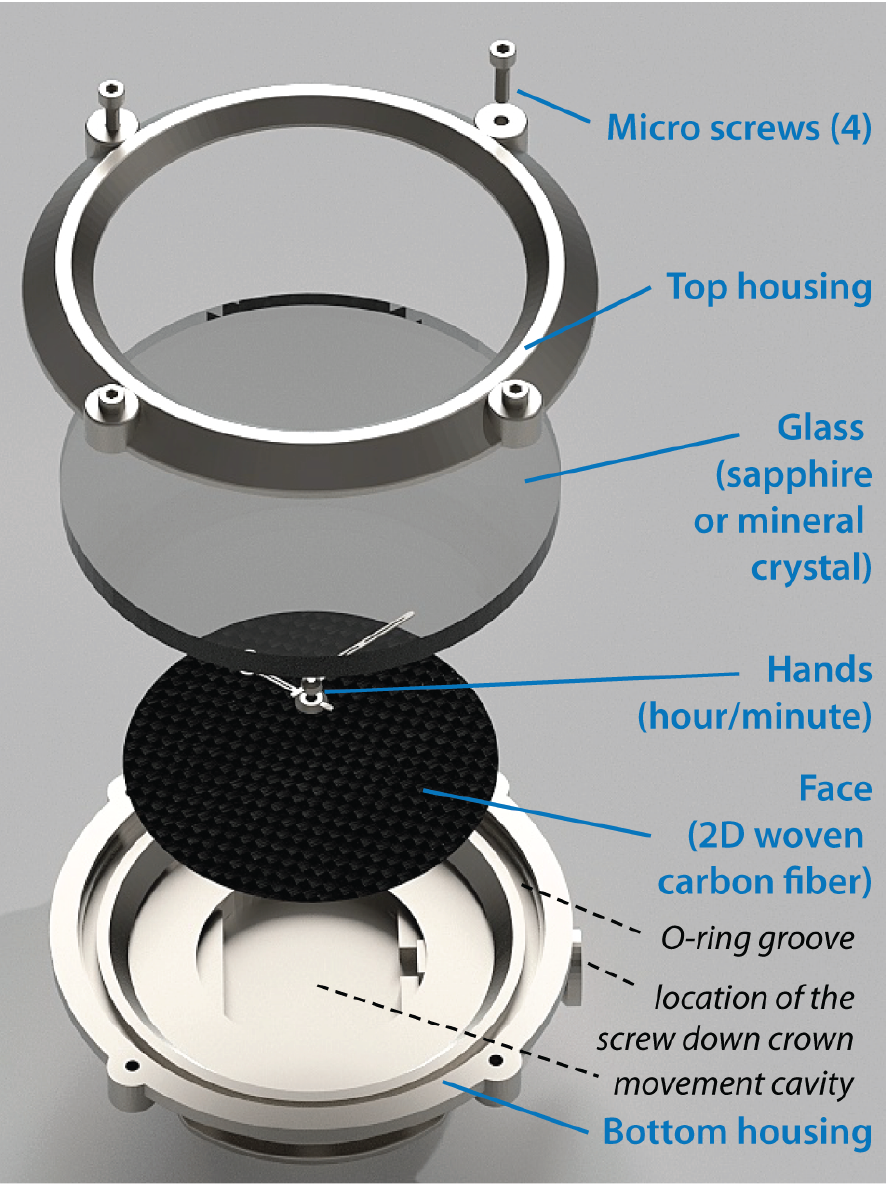

venus concept watch 1.0

The "venus concept watch 1.0" was a project from 2013 that I did with an RCA IDE collaborator. The idea was to draw comparisons between the extreme environments of space exploration and the conditions during deep diving on Earth. Some of the diver watches, just like planetary probes, are made out of titanium, sapphire for the windows, parachute nylon, and woven carbon sheet for the aeroshell or the watch face. The paper we wrote on the project highlighted the challenges of space exploration, advances in manufacturing innovation, including 3D printing, and discussed the making of this prototype.

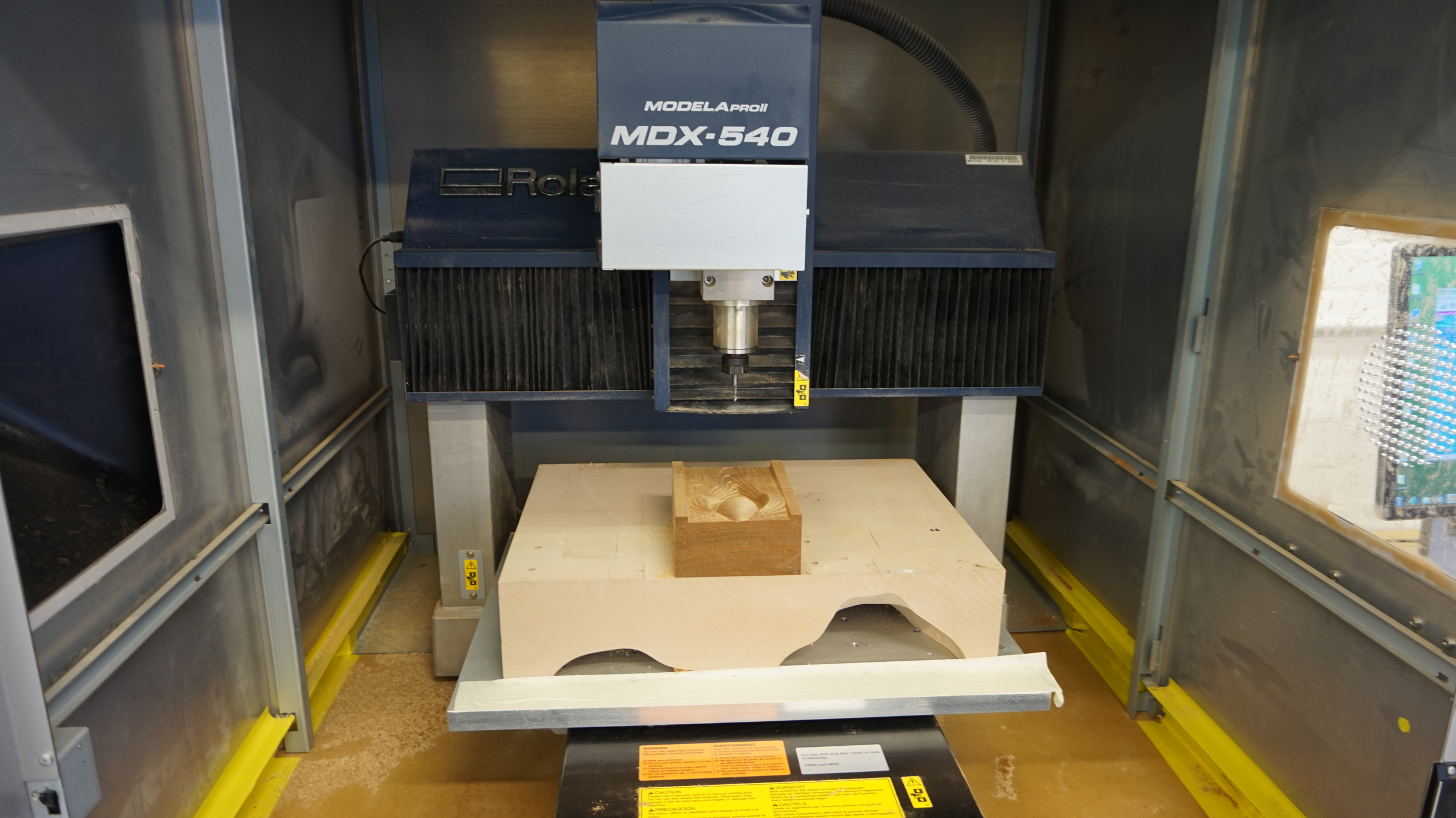

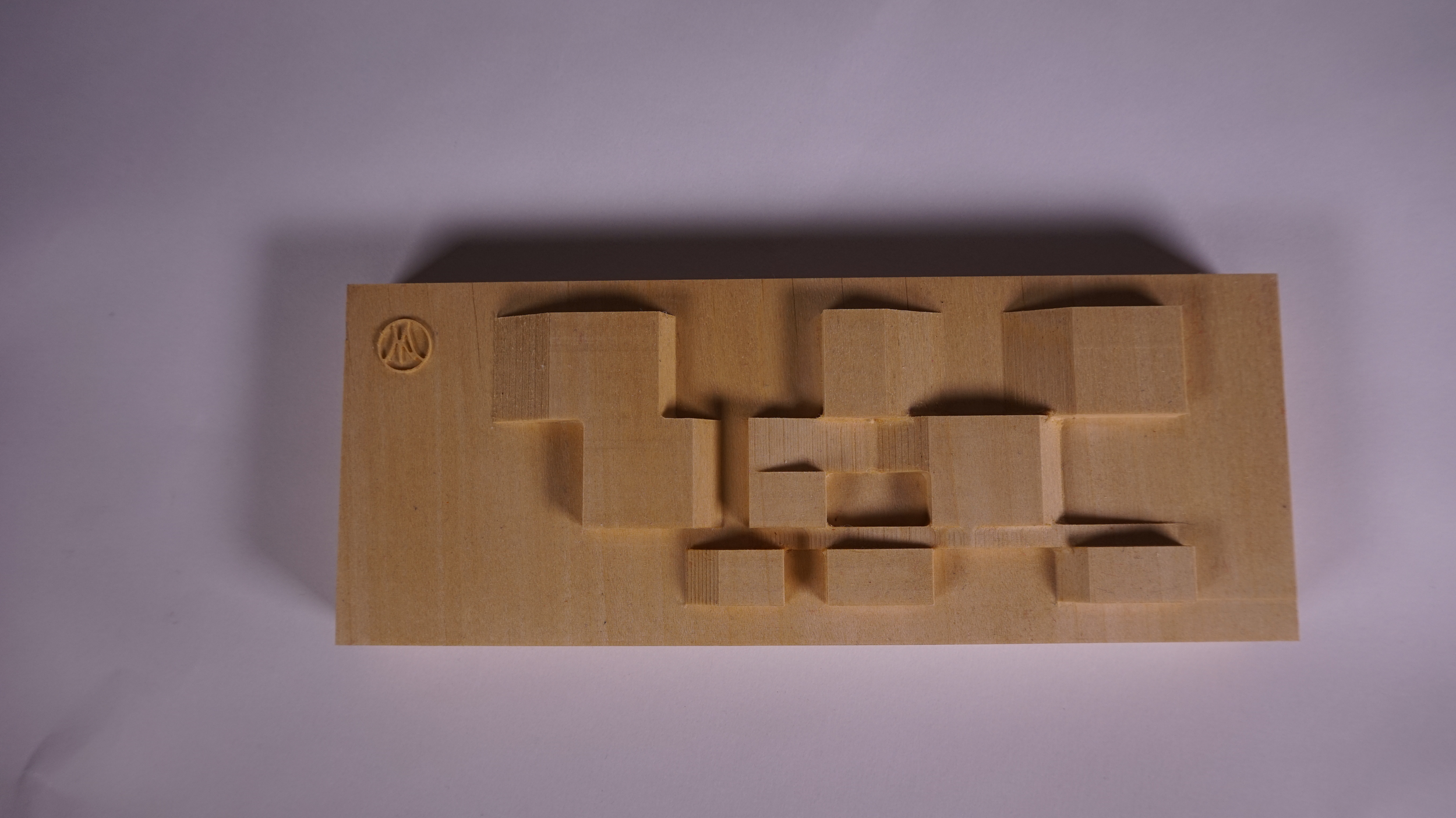

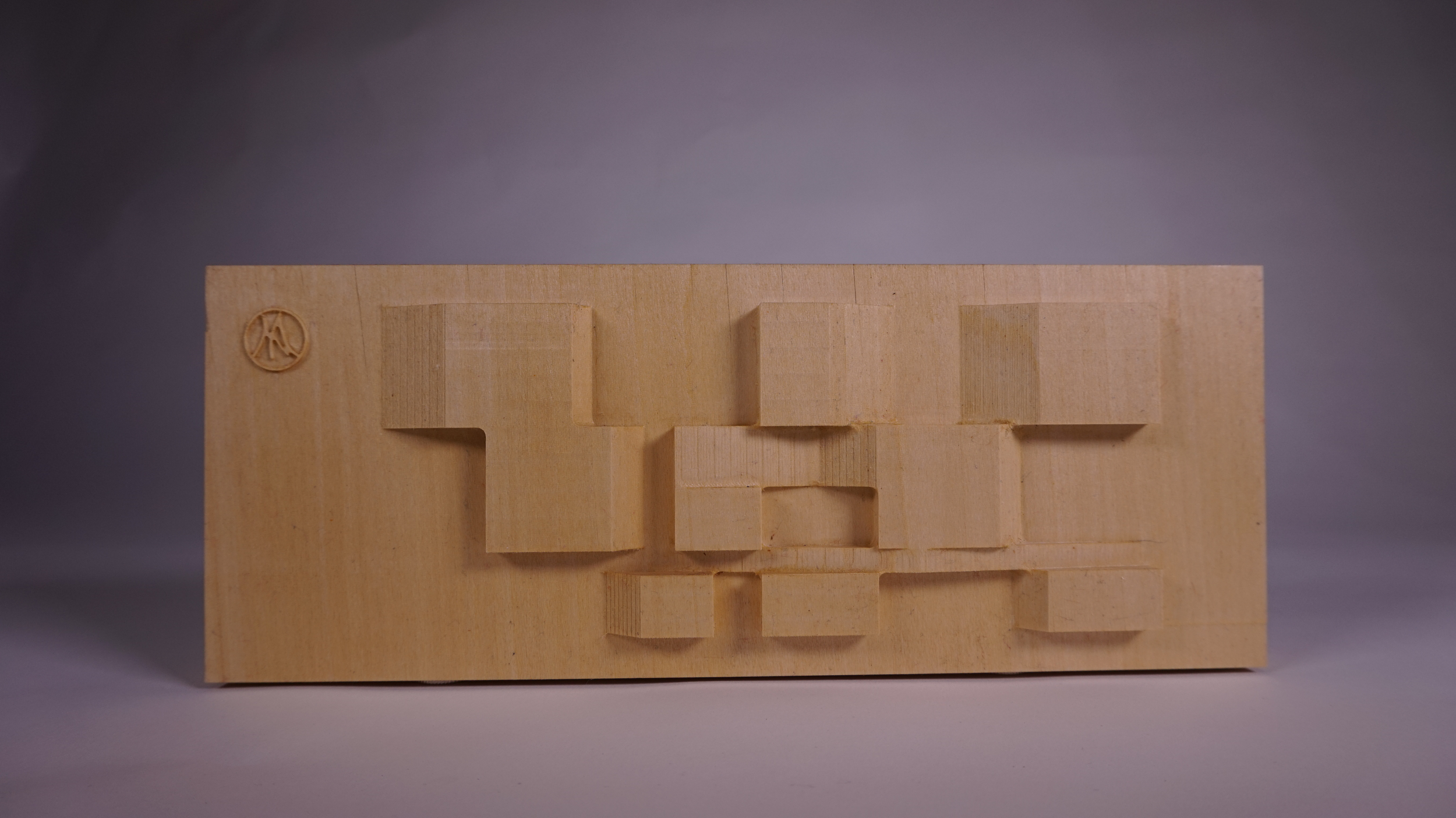

wood artifacts

I have created these wood artifacts to conceptualize some of my research ideas, and advance my making skills. The negative spaces artifacts, including the face and the aeroshells, show visual perceptional error. The terrain artifacts illustrate how we create simplified models of the world. The iroquois war club is based on a photo I took in Washington DC at the Smithsonian American Art Museum (SAAM), and modeled it in Blender3d from that. During the two sided-CNC machining I have decided to keep and enhance the supporting beams, and keep the leftover material around the artifact, to highlight and frame it. All of these artifacts were created in 2015/16 at RCA's Digital Aided Making workshops.